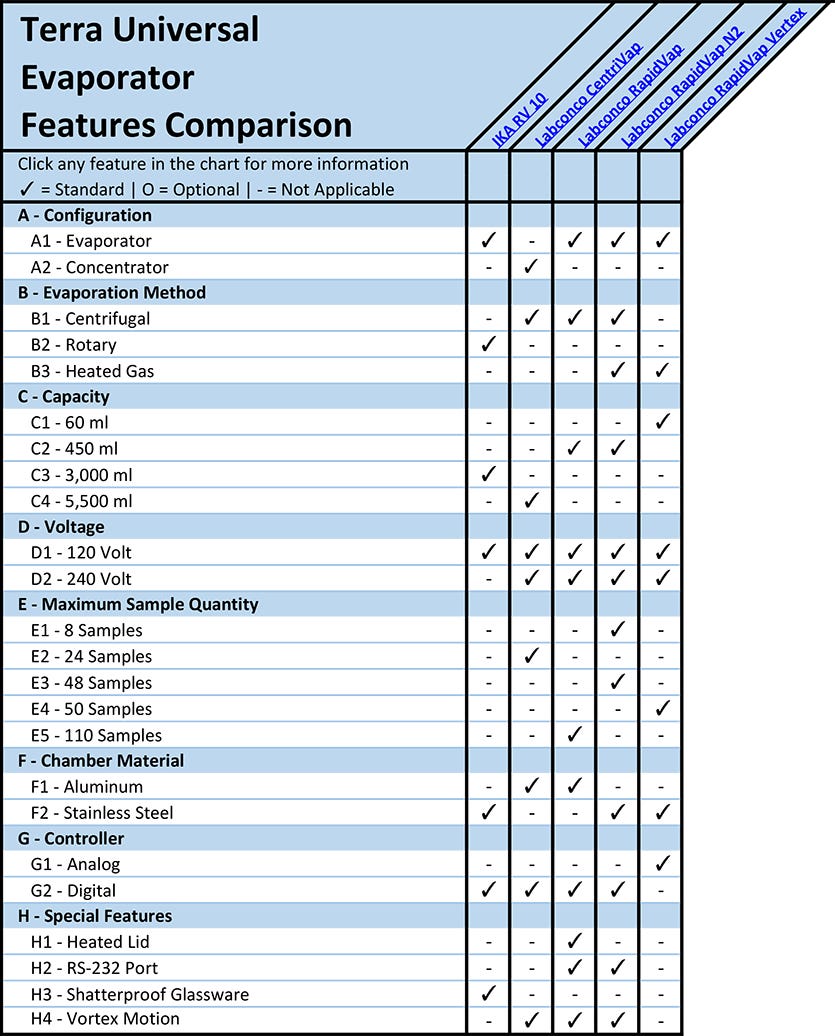

Laboratory evaporators remove solvents, such as acetone, methanol, DMSO or water, from aqueous samples for solvent recycling or distillation, sample purification, compound separation, or sample concentration.

How Do Lab Evaporators Work?

Lab evaporators use four primary methods to eliminate solvents: heat, centripetal force, vacuum, and nitrogen gas blow-down. Evaporators are designed as benchtop systems for daily use in pharmaceutical drug development, life science R&D, and wet chemistry laboratories.

A - Evaporator Configuration

(back to chart)

A1 - Evaporators

Evaporators apply heat directly to the sample, using a heating block or water bath, while generating a vortex motion within the sample tube, or flask. The vortex motion, which continuously mixes the sample, increases the sample’s surface area to boost evaporation rates.

Evaporators accommodate samples, housed in test tubes or flasks, from 5 ml to 3,000 ml in volume

What Are Laboratory Evaporators Used For?

Evaporators are used for environmental testing, toxicology studies, food chemistry and microbiology R&D, evaporation yields a small aqueous sample containing the analyte.

A2 - Evaporator Concentrators

Evaporator concentrators do not directly apply heat to the sample, but generate a centripetal motion within the sample tube to evaporate the solvent. The spinning motion decreases the sample’s surface area, reducing evaporation rates and lengthening evaporation times.

Evaporator Concentrator Capacity

Concentrators accommodate smaller sample sizes than evaporators, generally up to 50 ml in volume (and housed in microplates or centrifuge tubes).

How Are Evaporator Concentrators Used?

Evaporator concentrators are commonly used in life science for purification of peptide and nucleic acid samples, concentrators yield a small pellet at the bottom of the sample tube.

B - Evaporation Method

(back to chart)

B1 - Centrifugal Evaporators

Centrifugal evaporators utilize heat, applied to the samples through a heating block, and vacuum pressure, applied by a diaphragm vacuum pump, to remove solvent from the samples. The samples are loaded into rotors capable of spinning up to 5,000 rpm to ensure the liquid sample stays within the tube during evaporation. As the heating rate is tightly controlled through a digital controller, centrifugal evaporators are optimal for heat-sensitive samples.

B2 - Rotary Evaporators

Rotary evaporators, or roto-vaps, include a heating bath, dry ice condenser or chiller, solvent collecting vessel, vacuum pump and rotating distillation flask. The distillation apparatus rotates the flask above the heating bath to boil off the solvent – commonly acetone, ethanol, or DI water – which is captured and condensed back into its liquid phase by the dry ice cold trap or chiller. The collection vessel stores the purified solvent for further processing. Rotary evaporators accommodate samples up to 3 liters in volume (larger than the maximum sample capacities of nitrogen blow-down or centrifugal systems).

Rotary Evaporator Solvents and Chemicals

Roto-vaps are capable of capturing volatile solvents, like ether or methylene chloride, or polar aprotic solvents, like DMF.

B3 - Heated Gas Nitrogen Evaporators

Blow-down evaporators combine heat with a steady stream of nitrogen, along with vortex motion, to evaporate samples. More economical than centrifugal or rotary systems, nitrogen blow-down evaporators are not optimal for high-volume or high-boiling point samples.

C - Evaporator Capacity

(back to chart)

Nitrogen Blow-Down Evaporators

Nitrogen blow-down evaporators are ideal for smaller-volume samples between 100 ul and 10 ml; the total volume of all samples during a single evaporation run should not exceed 60 ml.

Centrifugal and Rotary Evaporator Capcity

Centrifugal evaporators and vacuum concentrators accommodate samples larger than nitrogen blow-down systems but smaller than roto-vaps; common runs should not exceed 450 ml. Rotary evaporators process high-volume samples up to 3 liters in volume.

D - Evaporator Voltage

(back to chart)

120-volt connections are suitable for standard laboratory power outlets in the United States.

208-volt or 240-volt connections require less current (amperage) and smaller conductors than equipment designed to operate at 120-volt.

E - Maximum Evaporator Sample Quantity

(back to chart)

Labconco’s RapidVap N2 nitrogen blow-down evaporator accommodates small runs up to 8 samples.

RapidVap Vertex models accommodate up to 50 samples.

For high-throughput labs, Labconco’s RapidVap system features a maximum capacity of 110 samples.

F - Evaporator Chamber Material

(back to chart)

F1 - Aluminum

Aluminum evaporator chambers are optimal for aqueous samples containing water or low concentration acidic solvents (between 0.1% and 1%).

F2 - Stainless Steel

Stainless steel evaporator chambers are optimal for aqueous samples containing high concentration acidic solvents (above 1%), like methanol or DMF.

G - Controller

(back to chart)

G1 - Analog Evaporators

Labconco’s RapidVap Vertex Evaporators include a pressure regulator, nitrogen switch controls to each of the 5 rows of gas nozzles, a temperature sensor, and a run timer.

G2 - Digital Evaporators

Digital controllers include LCD panels displaying current vortex speed, heating block temperature, and vacuum levels. Push-button controls allow users to design and save up to 9 different programs.

H - Special Features

(back to chart)

H1 - Heated Evaporator Lid

Lid heaters improve sample visibility and eliminate solvent condensation when applications involve high-boiling point solvents.

H2 - RS-232 Port

RS-232 ports are located on the rear of the unit for two-way communication with a printer or laptop computer.

H3 - Shatterproof Glassware

Optional shatterproof glassware is available for applications involving volatile chemicals.

H4 - Vortex Motion

Microprocessor-controlled programming regulates vortex speeds up to 1,000 rpm.

Find Evaporator Manufacturers Online

Laboratory-Equipment.com is a specialty division of Terra Universal. For nearly 40 years, Terra Universal has served the life science, pharmaceutical, biotechnology, and medical device markets. Customers appreciate a worldwide network of reps, factory-direct support, and ready-to-ship items available from Terra's manufacturing and warehouse facilities in Fullerton, California.

Shop a wide selection of evaporators online for a wide variety of food, pharmaceutical, laboratory, and analytical environments.

Contact a Laboratory-equipment.com specialist through web chat, email, or phone for pricing or a same-day quote.