How to Prevent Moisture Damage with a Desiccator Cabinet

On a grand scale, every desiccator cabinet looks similar: air-tight chambers, meant to keep components inside safe from humidity and particulate contamination during storage. It’s not until you need one that you consider what distinguishes one desiccator from the next, and how those differences will affect the material you need to preserve. So if you’re wondering what kind of desiccator cabinet is available, what problems to avoid and what features are used to achieve superior desiccation, read on.

When choosing a Relative Humidity (RH) control system, consider:

- How quickly RH setpoint needs to recover after the cabinet has opened

- When a desiccator door opens, humidity rushes inside and populates the chamber. It’s inevitable. The cabinet is designed to be air-tight, so moisture will linger inside until it’s purged or absorbed. How long can your product face exposure to humidity before a reaction takes place? Will it last a few hours? A few minutes? Different RH control systems absorbmoisture or dispense nitrogen at different rates, and you need to know how long your product will last so you can find the safest RH recovery rates for your desiccator system.

- How frequently you open the cabinet

- Most degradation takes place so subtly that by the time you realize something’s wrong, it’s too late. The time your products spend at the wrong moisture level accumulates as you access the cabinet, which can lead to slow degradation over months of storage.

- If you open the dry storage once a week to access mildly reactive products, you most likely won’t need to take extreme precautions when choosing your RH control system. But if you access your desiccator cabinet several times a day and have a 5% RH set point, recovery time will be critical to prevent prolonged exposure to moisture. Frequent access of the desiccator chambers could impede the internal environment from reaching a safe humidity level before it’s exposed again. That’s why Terra designs systems with rapid recovery in mind—to ensure that a dry cabinet dries quickly, giving your materials as much time as possible in optimal conditions.

- Required RH range for your stored material

- What RH range is required inside the cabinet? This could be determined by considering at what humidity level your products react. Humidity in the desiccator cabinet is measured as a percentage relative to the humidity in the ambient air.

- Different RH control systems offer different levels of control. A small and less serious application could use a molecular sieve or silica gel, which may only be reliable down to 15% RH. A highly sensitive application requiring less than 1% RH may require a highly efficient, automatic nitrogen gas purge system.

- Measuring below 1% may require more expensive systems, for example a vacuum chamber or extremely sensitive moisture sensor capable of measuring moisture at parts per million (PPM). As with the other control systems, the amount of time required to achieve the desired reading will depend on the volume of space being controlled and desired RH level. The time needed to achieve setpoint increases significantly below 5% RH.

Other Requirements for an RH Control System

To keep the inside of your desiccator dry, you need a method of delivering inert gas to your cabinet:

- Gas Generator: Requires a compressed dry air feed and an inert gas generator.

- Oil-Free Compressor — provides clean and compressed air, free of water and contaminating particulates, which feeds into a gas generator.

- Nitrogen generator — separates pure inert gas from the rest of the air molecules and delivers it directly to the desiccator cabinet. A Nitrogen generator offers many advantages compared to traditional pre-filled N2 tanks.

- Inert Gas Cylinders: Desiccator cabinet systems can connect to pre-filled argon or nitrogen tanks to purge chambers of ambient air.

The most common inert gas in laboratory applications is nitrogen. The gas purge is the fastest way to recover RH. Any desiccant cartridge would take hours or days to collect each moisture particle, whereas a purge could take mere minutes depending on the size and number of chambers in the desiccator. The moisture-laden gas leaves the cabinet through a Relief/Bleed (RB) valve while dry gas takes its place.

The most common design flaw in a multi-chamber desiccator cabinet:

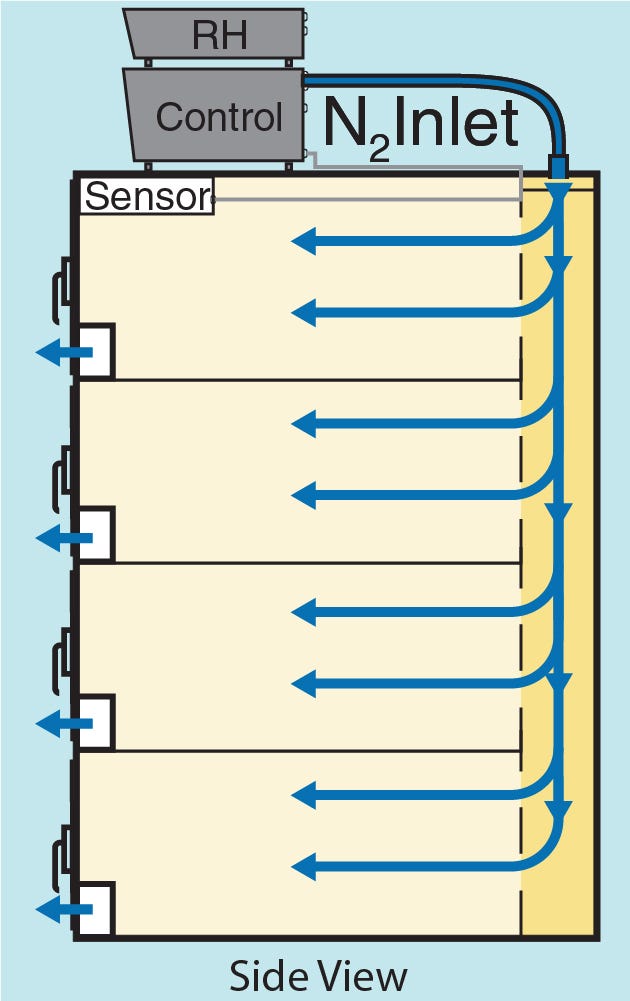

A multi-chamber desiccator often has a single relief/bleed (RB) valve located in the bottom chamber and the nitrogen supply streaming in from the top. In order to purge the cabinet, the nitrogen has to travel through every chamber, which passes all the contaminants and moisture from the opened door through each chamber, too, until it’s expelled through the bottom. The exposure isn’t serious for less delicate applications — if you plan on opening your chamber infrequently or your product isn’t exceedingly sensitive to contamination, this problem is less concerning. But in stricter scenarios, the issue must be remedied.

The fix:

The simplest solution? Install an RB valve in every chamber. RB valves continuously bleed off excess internal gas to maintain a safe positive pressure inside desiccator chambers, which also reduces strain on the cabinets’ seams and increases the desiccator’s longevity. In the event of negative pressure, RB valves will shut to prevent external air from entering the cabinet as it rests.

With an RB valve installed in each chamber, the moisture-laden gas leaves the cabinet twice as fast using half of the nitrogen consumption, so products stay safer while expending fewer resources. You can add RB valves to any desiccator to prevent both over-pressurization and the moisture spread created by the single point of gas release.

Terra’s desiccators work with RH control systems, which have their own unique benefits related to chamber isolation, levels of automation and purge speed:

Types of Relative Humidity Control for Desiccator Cabinets

Flowmeter – The RH essentials

Terra’s Flowmeters are our simplest gas regulators for manual control. They allow you to regulate RH by reading the flow rate and adjusting the inflow from your nitrogen source. Left on a very low setting, the flowmeter will maintain a constant positive pressure that halts the influx of moisture through permeation in the plastic walls of an acrylic desiccator (which are hygroscopic). This RH control requires manual adjustments. Dial the flowmeter to high flow to compensate for the rush of moisture when you access the desiccator, and wait for the RH levels to recover before you set it back to low flow. This basic configuration works well for long-term desiccator storage and infrequent access. Because it’s not an automated process, this is the most economically convenient option.

SmartDesiccator™ — The all-in-one benchtop automatic desiccator

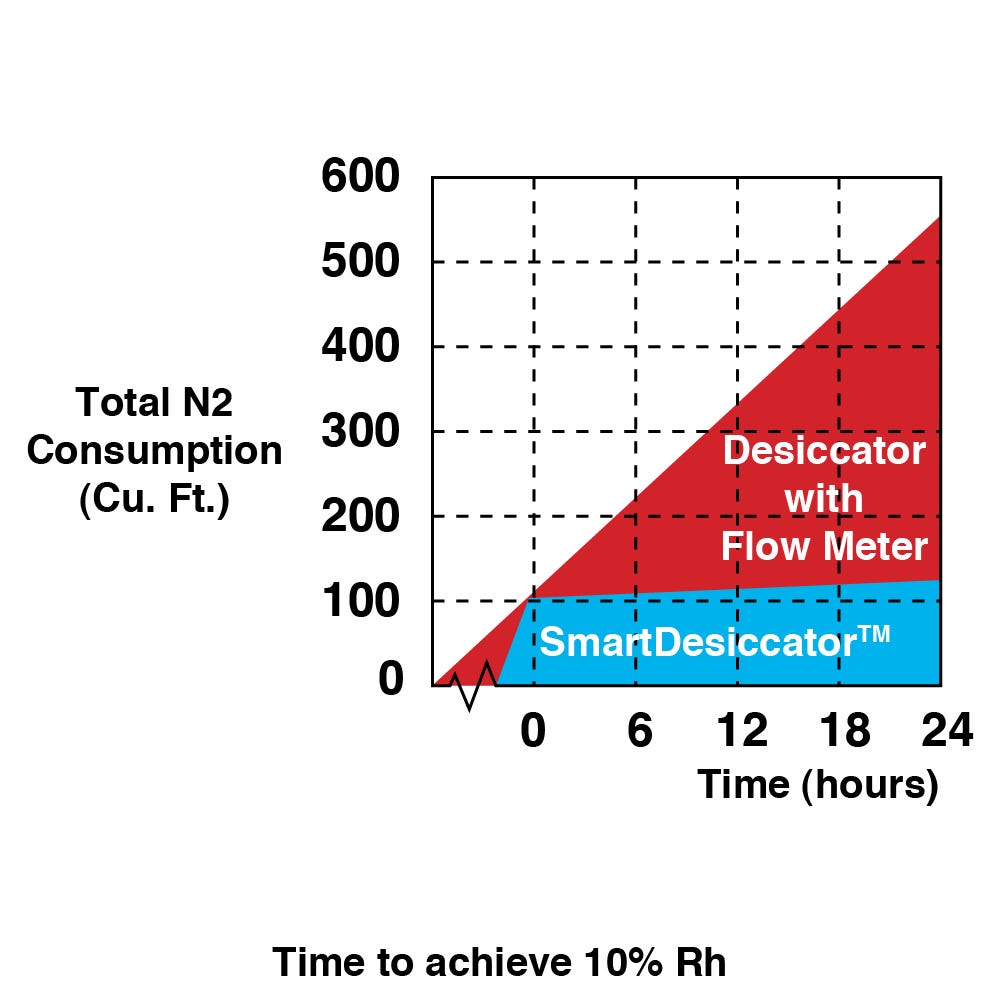

The quick-response feedback system of the SmartDesiccator™ quick-response feedback system continuously monitors the cabinet’s RH levels and activates a purge of dry nitrogen only when necessary. It knows when to turn on or off, so the purge won’t shut off prematurely or last too long, both of which waste gas. Comparison testing reveals that the SmartDesiccator™ maintains a low RH level using 22% of the nitrogen required by a flowmeter-based system of identical size. The SmartDesiccator™ all-in-one integrated LED display and sensor module eliminate the need for external control boxes. The design simplifies installation to a 30-second plug’n’play — just one gas and one low-voltage power connection and the SmartDesiccator is ready for action.

Dual Purge — High-and-Low, dual flow

The Dual Purge system offers two purge settings: high nitrogen flow level to accelerate to the desired RH setpoint and a low flow to maintain a steady RH and positive pressure in the cabinet..

Each door on the Dual Purge system has a sensor switch. During normal operation, with all doors closed, the system maintains an economical low flow of nitrogen into the desiccator to ensure a steady RH setpoint and constant positive pressure of 0.05” WG — just enough to block out moisture and contaminants.

When a door opens, the sensor switch immediately activates a high-flow purge of nitrogen into the desiccator’s plenum chamber.

When the door closes, the high-level gas flow continues to purge the desiccator for a selectable period of time, ensuring that any moisture that enters the chamber is quickly forced out of the RB valve before it can degrade your stored products. The time delay is adjustable, so you can retain the high flow for a longer time when you suspect moisture contamination may have occurred.

NitroWatch — Automate your RH adjustments

The NitroWatch system operates in tandem with the Dual Purge to fully automate moisture control. NitroWatch includes a humidity sensor that continuously monitors the internal RH level and activates the Dual Purge to automatically maintain any sub-ambient humidity threshold you require (down to 0% RH).

Simply program the desired RH level, and then let the system do its job. The fast-response, capacitive-type sensor detects the relative humidity; the level is indicated on a LED display. The NitroWatch controls the Dual Purge system to maintain the set point level — no matter how often doors are opened, or the system’s size, or what the ambient humidity is. It automatically dispenses nitrogen at high flow until the set point is achieved, and then it reduces back to low flow. It cuts back on wasted nitrogen by dispensing only what’s needed.

IsoDry — Rapid, uniform recovery

Accompanied by the Dual Purge and NitroWatch systems, the IsoDry desiccator cabinet system uses an exhaust plenum and fan to circulate dry nitrogen through the entire cabinet. This acts like a stirrer in a coffee cup. The IsoDry fan module quickly churns dry nitrogen through the chamber, removing humidity “blind-spots” and rapidly restoring RH after the cabinet is opened.

Status alerts built into the IsoDry Dual Purge System warn if incoming nitrogen line pressure falls below operational rates (signaling an interruption in the gas supply) or if the system remains in high-flow purge for an excessive period (signaling a door left ajar). This integrated system also suppliesthe low-voltage power required by the IsoDry fan module, as well as a variable speed control for the IsoDry fans.

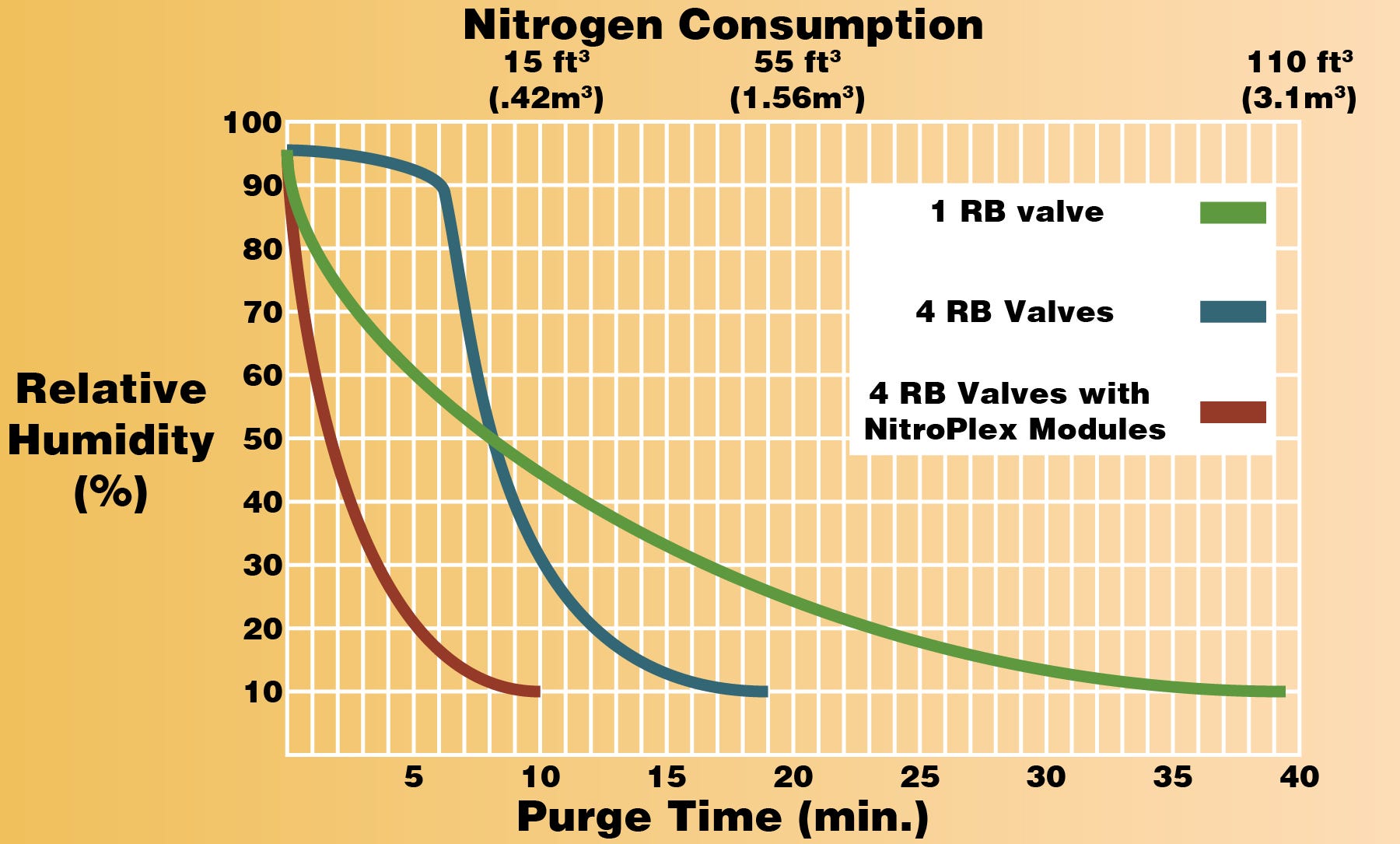

NitroPlex — Automated RH control in every chamber

NitroPlex desiccator cabinet with automated humidity control guarantees the integrity of stored components for the most stringent applications.

Each chamber boasts a microprocessor-based sensor/display module, to enhance desiccator performance and economize nitrogen expenses. It contains a miniaturized moisture sensor that reads the internal humidity level within ±2% of full scale. The LED readout displays this value or the programmable set point for that chamber. The set point is adjustable from ambient to 0% RH.

The ultra-efficient purging system incorporates Dual Purge and NitroWatch technology to ensure that your desiccator system maintains the conditions you specify, even during periods of frequent access or high ambient humidity. It also has an RB valve located in every chamber to eliminate the chance of moisture spreading through the rest of the dry cabinet. Each time a part is accessed and a door closed, the NitroPlex recovers the desired humidity level in a fraction of the time required by the other systems.

Chat with one of our specialists to find out more about Terra Universal desiccator storage, or call a representative at (714) 578-6100. Submit a QuickQuote request to get prices for the desiccator cabinet that best fits your purpose. We offer in-stock models ready to ship to you!