Monthly Archives: February 2016

-

Posted: February 25, 2016Read more »

The cleaning and sterilization of laboratory, clinical, surgical and compounding equipment is necessary to ensure patient safety and accurate results. In research laboratories, improperly cleaned or sterilized glassware and instruments opens the door to unwanted contaminants. Contaminated objects can also endanger laboratory personnel through exposure to mutagenic or toxic substances.

In clinical labs, contamination can lead to erroneous test results, jeopardizing patient treatment regimens or diagnoses. In surgical and pharmaceutical facilities, improper sterilization of equipment or compounding preparations can expose patients to a wide range of microbes and endotoxins. Thus, labs must develop and document washing and sterilization protocols that produce reliable results and ensure safety.

According to a Frost and Sullivan survey published in Lab Manager Magazine, 60% of laboratory budgets are spent on consumable products. Another 30% of the total budget is spent

-

Posted: February 22, 2016Categories: CleanroomsRead more »

Considering the countless designs and operating regulations, specifying the right clean room for your application is not a simple 1-2-3 process. But as with other capital purchases, a checklist of critical questions can help guarantee a decision that meets your expectations. Here’s what our clean room specialists first evaluate when designing a controlled environment:

How will my clean room be used?

The processes taking place in a cleanroom determine functional characteristics. For instance, static sensitivity or chemical processing dictate specific types of construction materials. Perhaps your needs can be met with a softwall cleanroom that features full-view plastic panels, or maybe you need an all-steel modular cleanroom for ultimate cleanliness. The number of personnel, their frequency of access, approved garbing protocol and necessary application equipment have a significant influence

-

Posted: February 15, 2016Read more »

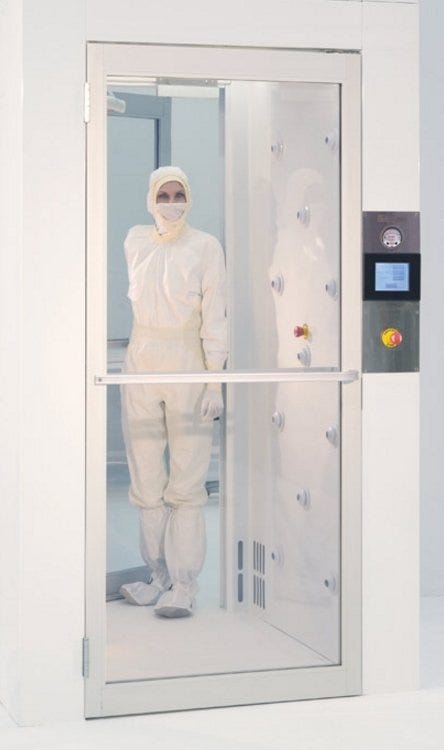

Cleanroom entrances present a significant potential for contaminant infiltration, so they must be managed with this in mind. Air showers are one way to minimize piggy-backing contaminants. They are enclosed chambers that use strong bursts of air to dislodge particulates from people or transport carts entering or exiting the room. Room entrances, and pass-throughs that incorporate an air shower, serve as a safeguard between critical and non-critical areas. Personnel are the greatest source of contamination in a cleanroom, so most of the methods of contamination reduction, including air showers, were developed to accommodate humans. Air showers range in size and construction, depending on the application, and are utilized by a diverse range of industries. So, how do air showers work? Find out below!

Air shower design and operation

Modular air shower chambers and tunnels use high-velocity streams of

-

Posted: February 11, 2016Read more »

The field of calorimetry is used to determine the heat resulting from chemical reactions and physical state changes, in addition to the heat capacity of non-combustible materials. Calorimetry has been studied for over 200 years and has proved useful in multiple scientific disciplines. From thermodynamics to modern combustion engines to food sciences, the utility of calorimetry in determining the enthalpy (heat transfer at a constant pressure) of a reaction cannot be overstated. Keep reading to discover two of the most common instruments used for calorimetric measurements, along with examples of their applications.

C 200 Calorimeter by IKA.

-

Posted: February 08, 2016Read more »

Gowning procedures are vital to cleanroom compliance, and a poorly designed gowning room can make following protocol challenging. Several factors contribute to the layout and furnishing of a functional gowning space, most notably the cleanroom’s application and your budget. Below, we breakdown of each area within and surrounding an “ideal” gowning room.

Pre-Gowning Area

The pre-gowning area is located directly outside of the gowning room. Personnel should be provided with a locker to store any personal items, such as clothing, jewelry, and cell phones, before entering the gowning room.

A motorized shoe cleaner and automatic contamination-control mat remove contaminating