ISO 14644 Types of Cleanrooms & Components | Comparison & Features Guide

Overview:

For companies considering the installation of a cleanroom, there are two primary design options: stick-built (brick-and-mortar) and modular construction. Since the first cleanrooms were installed in the 1960s, more companies have opted for stick-built rooms. However, modular systems are more popular now than at any time in the past. Each design methodology has distinct benefits; certain applications favor one design over the other, given the specific criteria for industry compliance.

In modular construction, pre-fabricated and pre-engineered wall panels, frames, ceiling grids and components are manufactured at an off-site factory under highly-controlled conditions. Each of the modular components are tested, validated, packaged for shipment, delivered to the jobsite, and assembled by factory-trained installers. The components are engineered to tight tolerances, allowing them to easily fit together during assembly.

The construction materials used in modular cleanrooms differ from stick-built designs. Modular wall panels are composed of non-shedding and non-reactive materials, such as static-dissipative PVC, acid-resistant polypropylene and thermal-resistant polycarbonate. The cleanroom frame and ceiling grid is fabricated out of 304-grade stainless steel or ASTM-rated powder-coated steel that is durable, non-absorptive and resists commonly-used cleaners and disinfectants.

Modular systems often carry higher up-front costs and longer fabrication times, as the specialty cleanroom materials specified are harder to source. The modular wall system doesn’t include space to run electrical connections, plumbing lines, networking cables and gas connections, resulting in exposed lines running down wall panels or dropped from ceiling tiles. Given the design of the framing system, flooring integration (including coving) can be more challenging for modular installations. However, modular systems offer a lot of advantages. As modular systems are made from pre-fabricated panels and framing, the installation time is much shorter than stick-built systems, which are built from scratch on a per-project basis. Modular systems provide the customer with flexibility to redesign, reorient, partially disassemble or completely move the cleanroom to a new facility without significant impact to the building. Modular rooms offer lower operational costs and require fewer routine maintenance visits than stick-built designs, which require consistent repainting. The rare maintenance performed on a modular room often does not require full cleanroom decommissioning, shortening the time before the cleanroom is again operational. As completely free-standing structures (with limited building integrations) using UL-listed pre-engineered components, modular cleanrooms make navigating the permitting and certification process easier for the user.

Stick-built (brick-and-mortar) cleanrooms involve the use of metal-stud framing covered by gypsum wallboard (sometimes known as drywall or sheetrock). For less-critical (ISO 7 and above) applications, a three-part epoxy paint is applied to the gypsum board to prevent cracks or crevices between the wall system and the ceiling grid or flooring. For the most critical (ISO 6 and cleaner) applications, a wall panel made of FRP (Fiberglas-reinforced plastic) or PVC is affixed to the gypsum board using a cleanroom-grade sealant. The wall panels are caulked using a seam treatment to prevent microbes from colonizing within gaps in the walls panels. Stick-built designs include either integrated hard ceilings composed of gypsum board or pre-fabricated ceiling grids, like their modular counterparts. Stick-built assemblies commonly include integrated flooring, such as coved epoxy-coated systems or interlocking cleanroom-grade tiles. As permanent structures installed within an existing building, stick-built cleanrooms integrate with the building electrical, plumbing, gas and telecommunication systems.

Stick-Built designs often carry lower up-front costs and shorter fabrication times than their modular counterparts, as the construction materials are readily available, easier to procure and less cost prohibitive. However, installation timeframes for stick-built designs are much longer than modular system, given the high amount of skilled labor required to complete the construction. Construction timeframes are commonly delayed by a lengthier permitting process, inspection hold points, and dry times associated with wet-applied coatings, such as adhesives, paint, sealants, caulk and spackle. On average, stick-built rooms take approximately 35% longer to install than modular cleanrooms. As compared to modular designs, stick-built cleanrooms carry higher operational and maintenance costs, due to annual repainting, re-caulking, dent and scratch repairs that are required. Any maintenance of a stick-built assembly requires cleanroom decommissioning, lengthening the time before the cleanroom is again operational.

Certain applications prefer stick-built designs, whereas other industries commonly opt for modular systems. For cGMP-compliant pharmaceutical and USP-compliant drug compounding operations, stick-built designs are the common choice, given the ease of installing coved flooring, spray-down resistant wall and ceiling panels, and the ability to hide plumbing lines and electrical cords. As drywall is prone to mold and mildew growth in moist conditions, applications requiring humid environments, like vivariums, animal husbandry, and cell culture research, choose modular systems. Biosafety level II and above facilities prefer stick-built rooms because integration with the building HVAC and exhaust scrubbing systems is paramount to maintaining operator safety and BSL-compliance. Companies working in dynamic environments, such as contract manufacturing, prefer modular systems as the increase in design flexibility allows for regular room reconfiguration.

Terra Universal offers both stick-built and modular solutions for every application and industry. Our pre-fabricated components, including wall panels, ceiling grids, filter fan units, lights, control systems, doors and windows are compatible with both brick-and-mortar designs and modular assemblies. Terra offers a top-to-bottom turnkey service, including engineering design, material fabrication, product testing, guaranteed shipment, delivery, installation, certification and project hand-off. Call a Terra product specialist at 714-578-6100 to discuss Terra’s wide range of cleanroom solutions.

A - ISO Rating

(back to chart)

ISO 14644-1 is a widely recognized international standard that specifies the classification of air cleanliness in cleanrooms and controlled environments. The standard provides guidance for assessing and controlling the levels of airborne particulates in these environments, which are crucial to industries such as pharmaceuticals, health care, microelectronics, biotechnology and aerospace.

The standard defines cleanrooms as enclosed spaces where the concentration of airborne particles is controlled to meet specific cleanliness requirements. ISO 14644-1 establishes the maximum allowable particle concentration per square meter of air space. The standard also defines the size range of particles considered within the classification, typically diameters of 0.1 micrometers and larger.

In addition to the classification system, ISO 14644-1 provides guidance on monitoring and validating cleanroom conditions, establishing procedures for testing and evaluating air cleanliness, and ensuring ongoing compliance with the specified cleanliness levels.

Terra’s products are designed to comply with the below ISO 14644-1 classifications.

A1 - ISO 4

The maximum allowable concentration in an ISO class 4 environment is 10,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 4 cleanrooms, or enclosures, must maintain an average airflow velocity of 50 – 90 feet per minute and an average air change rate of 300 – 540 changes per hour.

A1 - ISO 5

The maximum allowable concentration in an ISO class 5 environment is 100,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 5 cleanrooms, or enclosures, must maintain an average airflow velocity of 40 – 80 feet per minute and an average air change rate of 240 – 480 changes per hour.

A1 - ISO 6

The maximum allowable concentration in an ISO class 6 environment is 1,000,000 particles (greater than 0.1 micrometers in diameter) per cubic meter. ISO class 6 cleanrooms, or enclosures, must maintain an average airflow velocity of 25 – 40 feet per minute and an average air change rate of 150 – 240 changes per hour.

A1 - ISO 7

The maximum allowable concentration in an ISO class 7 environment is 352,000 particles (greater than 0.5 micrometers in diameter) per cubic meter. ISO class 7 cleanrooms, or enclosures, must maintain an average airflow velocity of 10 – 15 feet per minute and an average air change rate of 60 – 90 changes per hour.

A1 - ISO 8

The maximum allowable concentration in an ISO class 8 environment is 3,520,000 particles (greater than 0.5 micrometers in diameter) per cubic meter. ISO class 8 cleanrooms, or enclosures, must maintain an average airflow velocity of 1 – 8 feet per minute and an average air change rate of 5 – 48 changes per hour.

B - Air Flow Design

(back to chart)

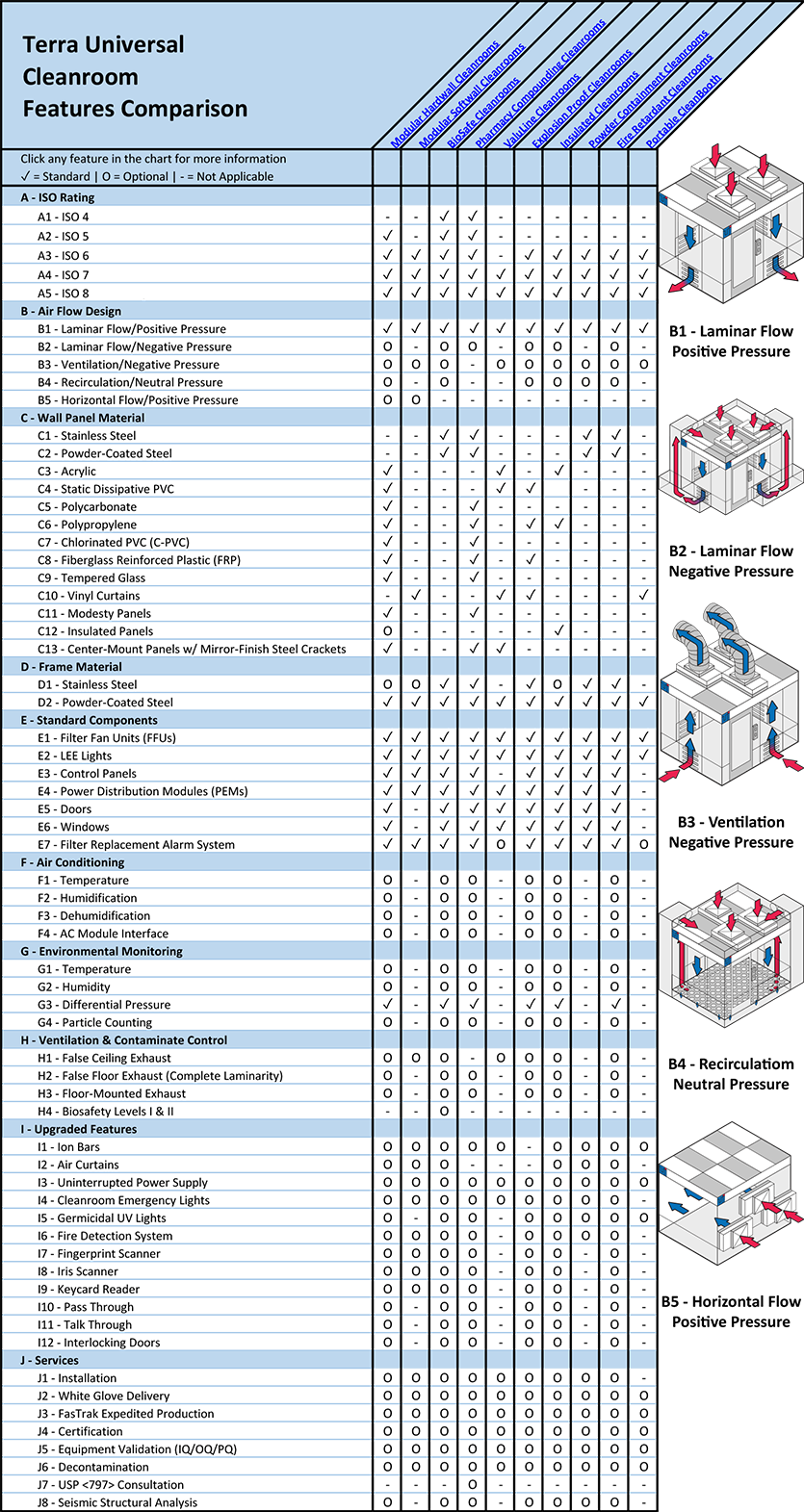

B1 - Laminar Flow/Positive Pressure

Laminar flow air and positive pressure cleanroom design are ideal for non-hazardous, ultra-clean applications. Positive pressure mitigates dirt from entering the cleanroom when opening doors or pass-through chambers. Laminar airflow design ensures that air maintains a singular, uniform direction and velocity from intake to exhaust port. Terra's positive pressure cleanrooms include HEPA filtration systems capable of ISO Class 3 - ISO Class 8 air quality conditions. ULPA filtration units are available for the most sensitive ISO 3 - ISO 5 product applications including pharmaceutical compounding, semiconductor wafer processing, sterile packaging, and micro-nanofabrication.

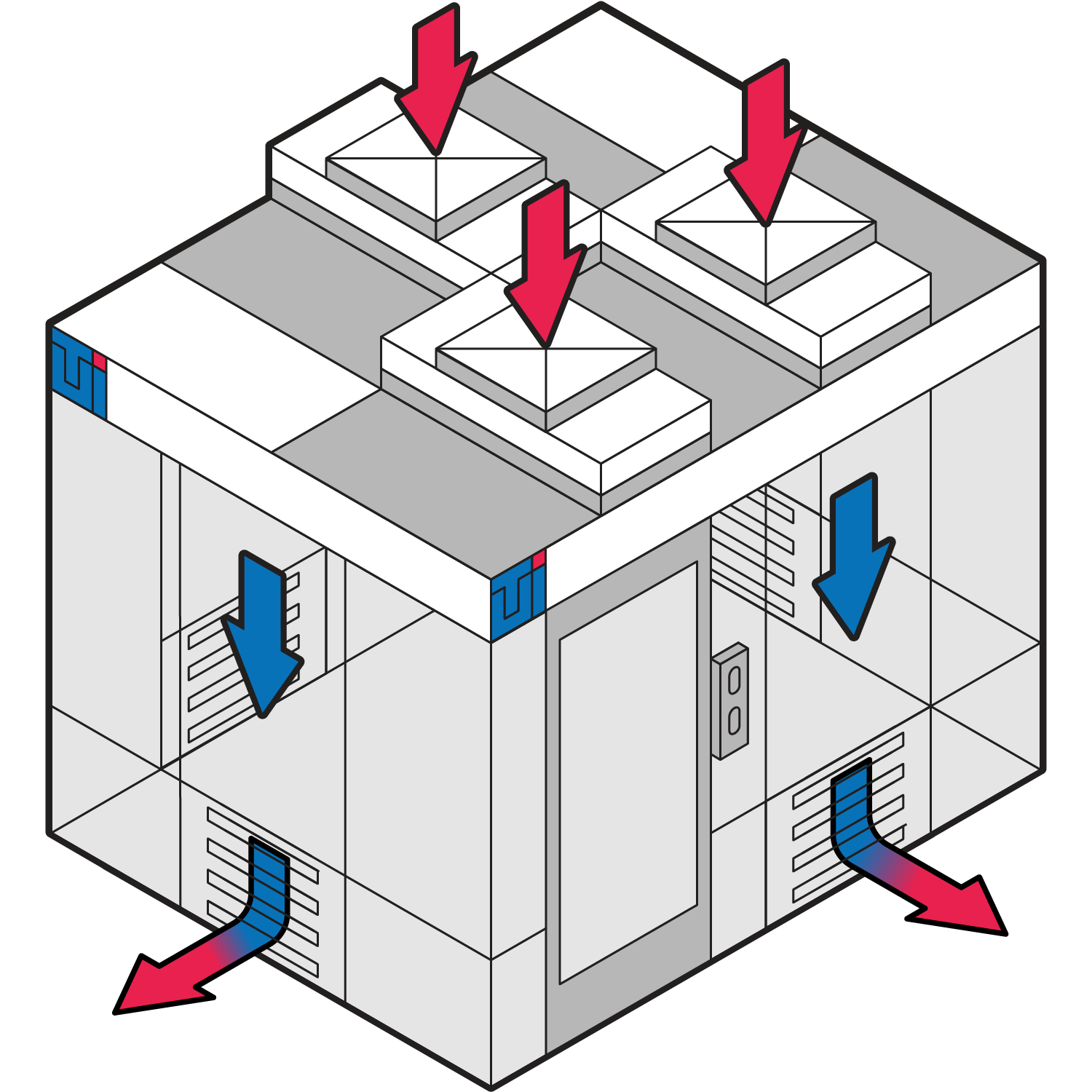

B2 - Laminar Flow/Negative Pressure

A negative pressure laminar flow cleanroom is best suited for hazardous environments. Particularly, when the product is also sensitive or reactive to chemical, environmental, or particulate contamination. Negative pressure cleanrooms prevent the escape of toxic or hazardous air from the containment structure. Laminar airflow design ensures that air flows without interruption between intake and exhaust, which ensures that sterile or biologically sensitive samples remain pure and unadulterated. Terra's negative pressure cleanrooms provide capable and safe production environments for reducing operator hazards in high-risk applications such as USP 800 compounding, infectious disease research, and chemically intensive processes that require volatile chemical handling.

Terra manufactures and designs cleanrooms to BSL-1 and BSL-2 criteria. Some operations that fall under BSL-2 may require single-pass air that is filtered before being exhausted to the outside; others may allow recirculation of air and release of unfiltered exhaust air.

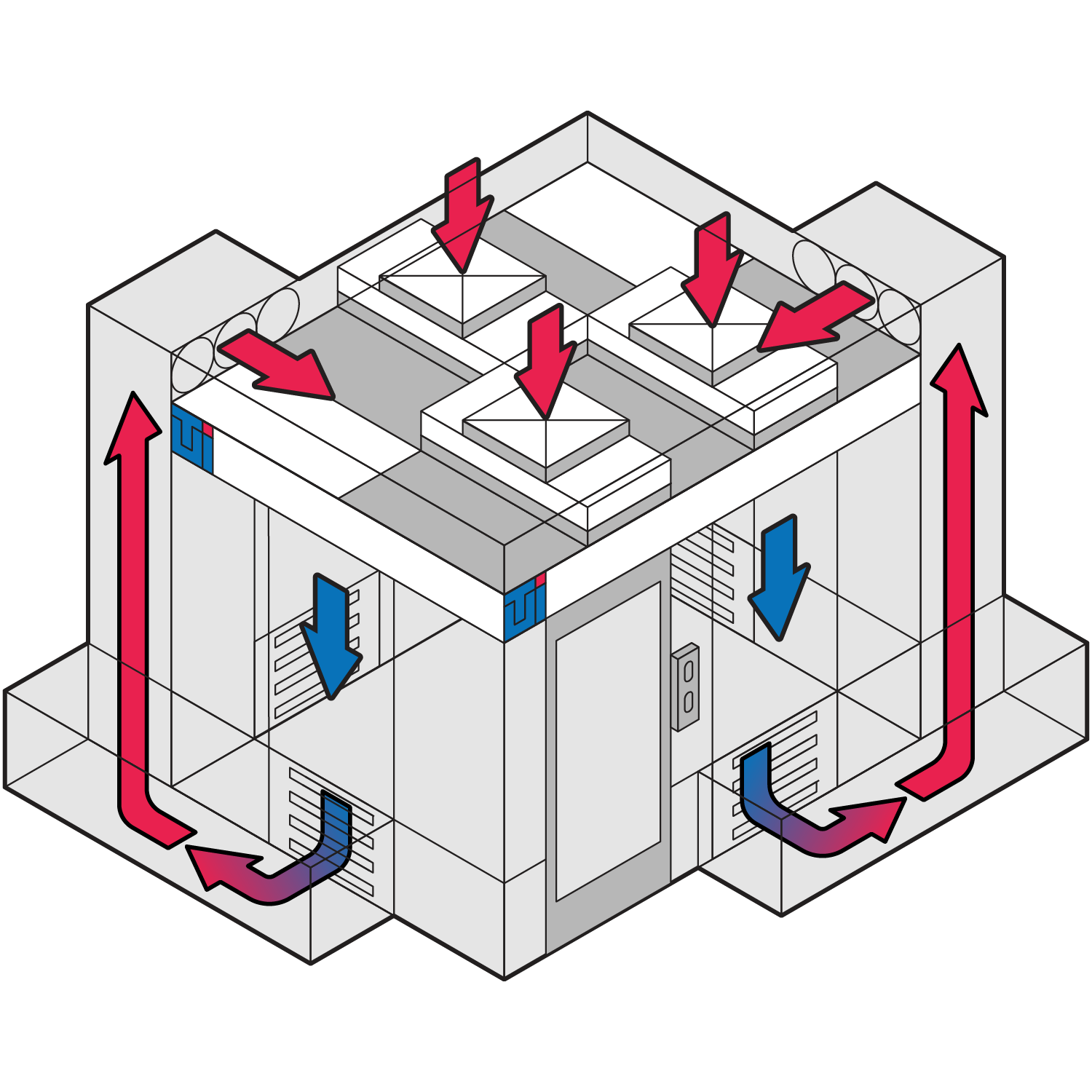

B3 - Ventilation/Negative Pressure

Negative pressure ventilation rooms are designed for handling chemicals that produce toxic, carcinogenic, or noxious vapors. Reverse-flow FFUs capture particles generated in localized cleanroom spaces to minimize contamination and ensure operator protection. Vapor removal FFUs eliminate trace amounts of VOCs from make-up air to prevent chemical fume contamination. Depending on the application, a containment room may require exit filtration: either HEPA/ULPA filters for particles and aerosols and/or carbon filters to remove chemical fumes.

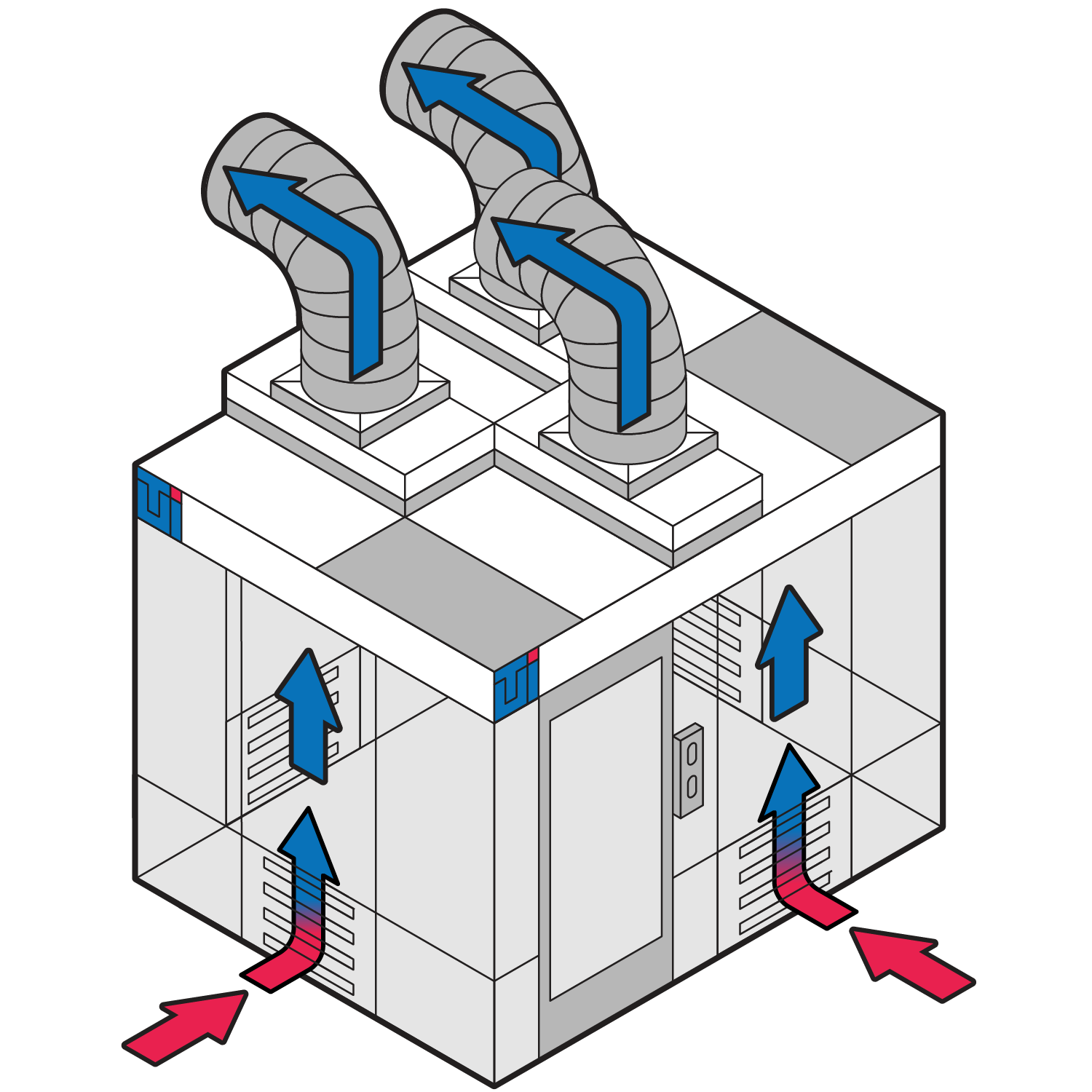

B4 - Recirculation/Neutral Pressure

A neutral pressure cleanroom system is designed to ventilate environmental nuisances away from the operator; it is not intended to provide personnel or environmental protection against hazardous substances. In some cases, the environment does not require any specific ISO-rated classification, thus the primary purpose is to isolate particulates and aerosols that would otherwise congregate in adjacent areas or corridors. If it is safe to do so, a recirculating cleanroom allows filtration and reintroduction of room air and reduces heating and energy costs. Neutral pressure is the least energy-intensive when compared to positive and negative pressure designs. Recirculating negative pressure cleanrooms are commonly selected for purity testing, weighing, capsulizing, and packaging pharmaceutical powders.

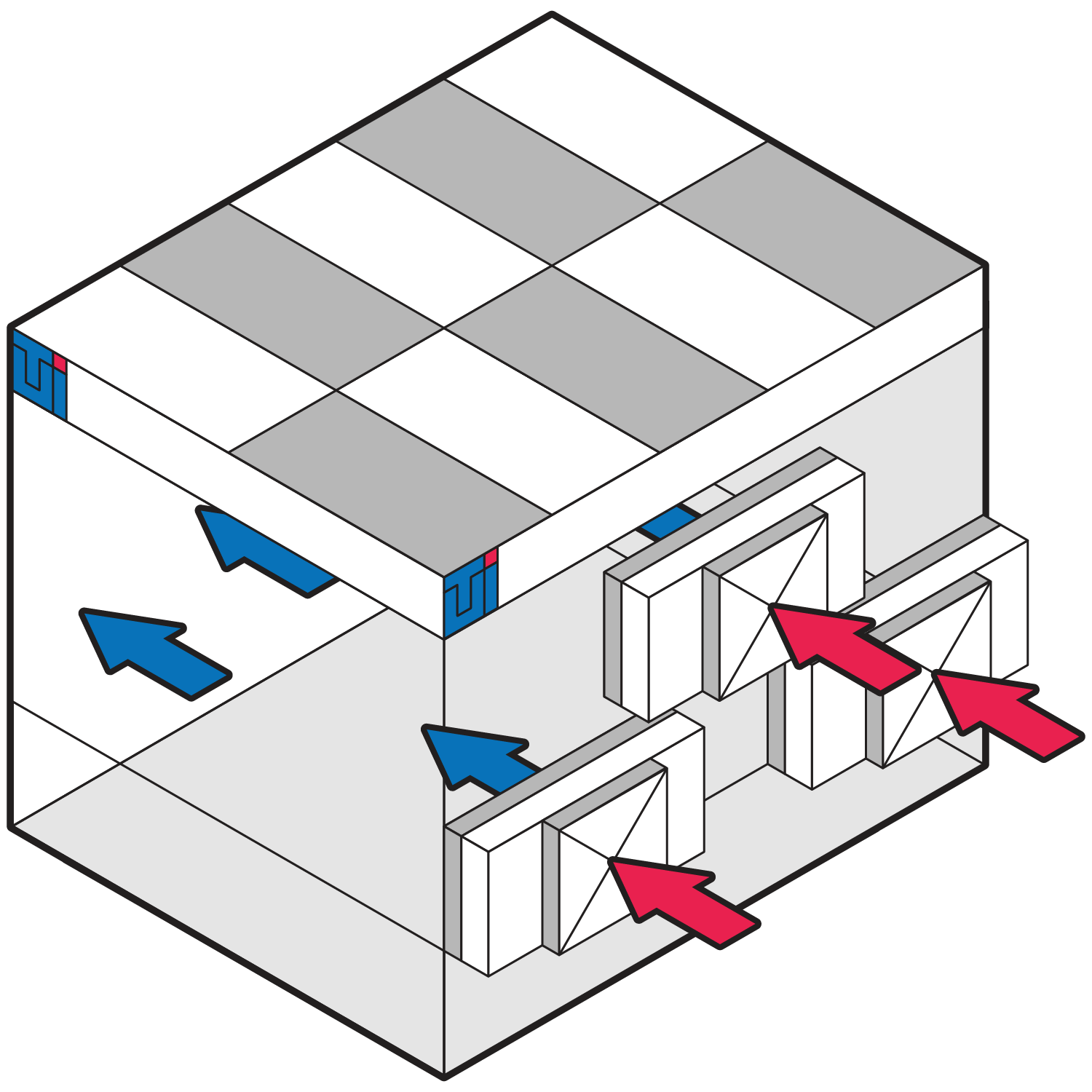

B5 - Horizontal Flow/Positive Pressure

Horizontally configured cleanrooms are advantageous when vertical space and ceiling access is limited or extra tall ceiling requirements. Ceiling height is an important consideration for cleanroom design, especially for large objects found within aerospace, satellite, and telescope manufacturing environments. Horizontal flow cleanrooms introduce air from fan filter units mounted within sidewalls instead of traditional ceiling-mounted blowers. Air moves in parallel with the floor instead of perpendicularly. Air flows from a side-wall integrated with HEPA fan filter units and exits through a parallel wall with an integrated plenum for air return or exhaust. Wall-to-wall laminar airflow is advantageous when handling small parts and liquids which would otherwise be problematic for vertical floor cleanrooms with grated false-flooring.

C - Wall Panel Material

(back to chart)

C1 - Stainless Steel

Stainless steel is a golden standard among cleanroom construction materials. Easy cleaning, favorable heat properties, and chemical resistance make stainless an ideal choice for biopharmaceutical and semiconductor environments. The smooth surface is easy to wipe down, resists biofilm buildup, and will not off-gas.

C2 - Powder-Coated Steel

Powder-coated steel is an economical choice that also provides favorable heat and chemical resistance for most applications. Terra’s signature white powder coat finish provides a high quality, durable barrier to protect against corrosion, plus a clean and attractive aesthetic. The advanced heat-fused formulation exceeds ASTM and ISO paint standards to resist chipping, scratching, fading, and wearing.

C3 - Acrylic

Acrylic is widely used in cleanrooms and other critical environment applications. Its low initial cost, lightweight, transparency, and tensile strength makes it an attractive choice in many situations. Terra offers economical acrylic enclosures as a budget-friendly option. While acrylic is fairly durable against UV light and impact-resistant, the material is easily degraded by alcohols and solvents.

C4 - Static Dissipative PVC

Static-Dissipative PVC comes in rigid or flexible material for use on hardwall cleanroom panels or cleanroom curtains, dust covers, microenvironments, and other applications requiring a softer material. Non-dissipative plastics quickly accumulate surface charges that attract contaminants. Dissipative plastics prevent static build-up that attracts airborne particulate and lint fibers, which makes surfaces easier to wipe down. Static-dissipative PVC (SD-PVC) will not hold a static charge, offers wide chemical compatibility, and cleans easily. SD-PVC retains a surface resistivity of 10^6 - 10^8 ohms/square indefinitely unlike spray-on coatings that can wear off after a few years. SD-PVC also resists alcohol and most other sterilizing solutions, thus supporting standard disinfecting procedures and extending the life of your enclosure.

C5 - Polycarbonate

Polycarbonate is transparent with a slight gray tint and offers broad-spectrum chemical resistance, high impact resistance, and excellent thermal resistance (to 200°F / 93.3°C). Polycarbonate is stronger and cracks less easily than both acrylic (15x stronger) and glass (250x stronger).

C6 - Polypropylene

Polypropylene is an opaque thermoplastic with excellent chemical resistance against acids and solvents.

C7 - Chlorinated PVC (C-PVC)

Cleanroom chlorinated polyvinyl chloride (C-PVC) wall panels are tested and certified to meet ISO 5 – 8 cleanliness standards. These compressed panels have excellent chemical resistance and prevent particle emission and microbial growth. Their unique solvent-free silicone adhesive allows installation on wallboard substrate creating a strong, rigid structure when mounted to Terra’s steel frame. Welded seams are trim-free, without cracks or gaps. Optional PVC coving is available for floors and corners to further simplify cleaning.

C8 - Fiberglass Reinforced Plastic (FRP)

Class A and C FRP panels feature a unique non-outgassing advanced polymer adhesive for installation on drywall or other substrates. A specialized seam sealant provides trim-free seams that expand and contract to accommodate temperature-induced dimensional changes without creating cracks or gaps. A patented surfacing technology seals panels uniformly to enhance durability and prevent particle emission and microbial growth.

C9 - Tempered Glass

Tempered cleanroom glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. Tempered glass is not only impact resistance, but also ideal for its high visual clarity and aesthetic. Glass wall cleanrooms allow easy monitoring of operators and processes within the cleanroom and tend to appear larger and more spacious. Tempered glass is non-outgassing and chemical-resistant, making it ideal for frequent decontamination.

C10 - Vinyl Curtains

Cleanroom vinyl curtains are lightweight and rapidly installable for creating room partitions, isolating equipment and processes, or mobile isolation when configured with wheel casters. Curtain strips are available in either 4' -wide softwall panels made of blur-free 40 mil vinyl or 8” -wide strip curtains made of blur-free 60 mil vinyl. Static-Dissipative PVC vinyl includes built-in static inhibitors and is recommended for all cleanrooms to minimize particle cling. A T-Grid Mounting System allows suspension of curtains or strip shields from Terra's cleanroom ceiling grid.

C11 - Modesty Panels

Modesty panels provide the combined benefits of natural light while also maintaining a degree of privacy. These panels are ideal for multi-level cleanroom mezzanines that require additional office space or unclassified storage. Modesty panels include an opaque lower panel and upper panel of transparent glass or cleanroom-rated plastic such as polycarbonate or static dissipative PVC. A solid lower panel provides a balance of privacy while the transparent window allows the introduction of natural light and tends to make the space appear larger and less constricted.

C12 - Insulated Panels

A double-wall, insulated wall panel promotes a stable environment for long-term sample storage, cell cultivation, or high-volume process equipment. Terra's double-wall insulated panels are adaptable to the customer’s temperature range specifications and application requirements including cold rooms, incubation, and sound isolation. Double-wall construction with 1”-thick polyurethane insulation enhances cleanroom heating/cooling efficiency and thermal stability. Rigid foam insulation paired with a climate control system provides better temperature stability for applications that require raised flooring for true laminar flow. Double-wall structure allows air to circulate through the inter-wall plenum which further increases filtration and A/C efficiency in high-performance applications.

C13 - Center-Mount Panels With Mirror-Finish Steel Brackets

Most of Terra’s competitors affix the cleanroom wall panels directly to the frame (mounted on the internal or external side of the frame. With this design, replacing cleanroom wall panels is a cumbersome task and requires cleanroom shutdown. If the panels are affixed externally to the frame, installing coved flooring is virtually impossible and the customers are tasked with sterilizing the frame along with all of its crevices. If the panels are mounted internally, the customer loses precious cleanroom space. If the flooring is coved to the internal panels, the customer loses even more space. Terra’s center-mount panel design alleviates these issues.

D - Frame Material

(back to chart)

D1 - Stainless Steel (<20% or -5" Hg)

Unlike most competitors who offer only aluminum extruded frames, Terra Universal provides steel and stainless steel frame materials that maintain structural integrity far longer than aluminum under fire conditions. Terra Universal’s BioSafe stainless steel cleanrooms may be ideal for sterile applications since they are not affected by harsh wash-down chemicals.

Double-Wall Steel Panels

Double-wall panels, available in 304/316 stainless or powder-coated steel, create a freestanding structure for affixing a ceiling grid. Each panel consists of an inside and outside portion, which are joined by a compression ball-and-socket fastener. Once joined, the walls can be detached by means of magnetic-grip handles (not included). The hollow space created by these panels provides a convenient installation zone for electrical conduit, gas, and vacuum service line enhancing systems, cleanliness, and appearance. In controlled temperature applications, this void may be insulated to optimize thermal stability and reduce energy costs.

All Steel BioSafe Cleanrooms

Terra’s all-steel BioSafe® Modular Cleanroom creates a rigid, self-supporting structure without a separate frame or external bracing, a key advantage over other designs that require special permitting and contractor installation.

316L Stainless steel contains the same corrosion-resistant materials as 316 but includes the added benefit of lower carbon content—eliminating the opportunity for excessive metallic contamination and making cracking less likely. Both 316 and 316L can withstand chlorides and chlorinated solutions, such as Spor-Klenz® and Isopropyl Acetate.

D2 - Powder-Coated Steel

Terra's powder-coated steel cleanroom frames support free-standing softwall spans of up to 20 feet without internal posts or ceiling suspension cables. If necessary, reinforcements are provided for high-clearance, long-span rooms. Reinforcements ensure stability and additional seismic requirements for particle-sensitive samples and analytical instruments.

- Excellent for cleanroom applications

- Good weather resistance

- Good mechanical properties

- Good chemical resistance

- Excellent UV protection

- Good storage stability

- Underwriter Laboratories recognized component (UL approved)

E – Standard Components

(back to chart)

E1 - Filter Fan Units (FFUs)

Terra’s WhisperFlow® FFU’s feature UL-listed components and built-in baffles that quietly produce uniform laminar airflow across the face of the filter. UL-listed products meet the highest manufacturing standards and reduce the risk of damage, injuries, and electrical hazards.

Smart® Fan Filter Units with EC Motors provide annual energy savings of nearly $500 per fan filter unit. The control card features industry-standard MODBUS® networking, precision speed control (1-100%), and closed-loop control capability for air pressure, airflow, and particle count sensors.

Terra fan filter unit housings are configurable for room-side replaceable, explosion-proof, heated, and low-profile configurations. The same high performance fan filter units are found throughout Terra products including cleanrooms, laminar flow hoods, and containment systems. Filter fan units are stocked, pre-tested, crated, and ready for immediate shipment from Terra's distribution centers.

- Explosion-proof fan filter units are rated for hazardous areas and reduce fire or explosion risks

- Reverse flow fan filters evacuate contaminated air.

- Portable HEPA fan filter units allow rapid deployment and filtration of stagnant air.

E2 - LED Lights

Terra's LED flat panel troffer lights include dimmable brightness and 5 selectable color temperatures to achieve the perfect balance of light including 3000K / 3500K / 4000K / 5000K / 6500K. When paired with Terra's cleanroom control panels, lighting control is available from a centralized location out of the cleanroom. Terra's power distribution modules (PDMs) allow connection of lighting and fan filter via quick connections that do not require hardwiring. LED panels are available with integrated backup batteries that allow for up to an hour of continued visibility in the case of a power failure.

E3 - Control Panels

Cleanroom Control Panels centralize control of cleanroom lighting, power, fan speed, and assignable groups.

Standard Control Panels provide central control and connection of lights and filters. A Fan Filter Replacement Alarm provides a reliable, quantitative method for determining when a HEPA filter requires replacement. An optional Night Service Switch drops all Fan/Filter Units (FFUs) into a low-energy mode for nights and weekends.

Smart® Control Panels connect to EC FFUs for individual or grouped fan control and remote monitoring of room differential pressure, particle counts, temperature, and humidity. Robust systems offer advanced control for up to 200 fan filter units and 16 independently controlled rooms.

E4 - Power Distribution Modules (PDMs)

PDMsallow the addition of ceiling fan/filter units and lights to meet any cleanliness requirement or to upgrade ISO levels or lighting levels after installation. Terra’s PDMs use 3-pin or 4-pin quick connect fittings to power all FFUs, and lights, no matter the cleanroom size. Hardwiring is only required to connect the Primary, Secondary, Booster, and Duplex PDM modules. Because no additional hard wiring is required to connect and disconnect power to additional lights and fan filters, contractors save time, money, and resources during cleanroom installation, expansion, or modification.

E5 - Doors

Standard doors with aluminum frames are available in either single or double door configurations and a choice of acrylic or static-dissipative PVC panels.

Swing doors are either Left Hand Reverse (LHR) or Right Hand Reverse (RHR) when viewed from outside the cleanroom (dirty side) to minimize particulate impact on the cleanroom when the door opens.

Cleanroom doors on prehung frames install easily for negative or positive pressure cleanrooms. Choose from swing-out or sliding doors that are UL leak-rated and suitable for ISO 4 - ISO 8 environments.

BioSafe® 316L stainless steel doors have continuous seam welds for sterile and aseptic environments. Terra's BioSafe products forgo cracks and crevices known to harbor particles and microbes. Dual-pane, flush-mount windows minimize horizontal surfaces and crevices where contaminants collect.

Fire-rated doors include insulated double stainless steel walls, wire-free construction, and a fire-rated glass-ceramic viewing window that is impact resistant.

E6 - Windows

Terra's cleanroom windows are compatible with any cleanroom wall material or thickness and designed for compliance within healthcare, pharmaceutical, and GMP manufacturing applications. These easy-to-clean, hygienic windows enhance the visibility of operations and foot traffic without jeopardizing GMP design standards.

Flush-mount cleanroom windows easily and seamlessly install into modular and stick-built cleanrooms and labs. Developed specifically for aseptic requirements in bio-pharmaceutical and cGMP cleanrooms, these hygienic cleanroom windows bring more light and visibility to your workspace without compromising cleanliness requirements. Choose from easy-to-clean framed or frameless stainless steel designs. Fire-rated cleanroom window designs meet building code requirements to protect your employees, operations, and business.

E7 - Filter Replacement Alarm System

Fan filter replacement alarms provide automatic replacement alerts to avoid costly and unexpected operational interruptions. Alarms trigger an audible buzzer when differential pressure reaches an adjustable setpoint. Alarms provide a reliable method for establishing fan filter replacement intervals while also reducing the risk of electrical/fire hazards caused by overworked motors pushing against overloaded HEPA filters.

BioSafe® cleanroom windows include compression fittings for fast, hardware-free installation. Framed and frameless designs are compliant with BSL-rated rooms and ISO 4-compliant spaces.

Related: Cleanroom Window Types and Flushmount Advantages

F – Air Conditioning

(back to chart)

F1 - Temperature

Terra will work with a local HVAC contractor to provide an air control system that meets your cooling requirements and local codes. If the existing HVAC system cannot be used, Terra will provide the ducting and recirculation system that routes exhaust air to the compressor and delivers cool air to the ceiling FFUs in ample volume to maintain the desired air velocity inside the enclosure. Additional Cleanroom A/C Module provides economical cooling in facilities without adequate HVAC. Based on the cleanroom size, desired temperature, and heat dissipated inside the cleanroom, Terra will configure the appropriate number of AC units required for the space. With larger cleanrooms, Terra works with a local contractor to install a split A/C system, which moves the heat-generating compressor outside the building to reduce heat loads inside the facility.

F2 - Humidification

Terra’s Ultrasonic Humidifier is designed to be a turnkey system as an addition to your cleanroom. Simply place and rest the unit on an open 2’x4’ ceiling grid from above the cleanroom. No fasteners or gaskets are required to secure the unit in place. The system uses five ultrasonic transducers to generate mist and operates on only 150W, less power than conventional steam canister humidifiers. Humidification and dehumidification modules are controlled by a humidistat independent of the thermostat. The Ultrasonic Humidifier comes with a remote control to turn on the unit and set your desired RH levels (up to 100% RH).

F3 - Dehumidification

Cleanroom Dehumidification Modules use silica gel desiccant housed in a rotor to produce dry airflow.

F4 - AC Module Interface

Air Conditioning Modules provide economical cooling in facilities without adequate HVAC. Air Conditioning Modules incorporate dehumidification circuitry and are controlled by a humidistat independent of the thermostat. The unit includes a powder-coated steel air distribution plenum mounted to the external cleanroom wall, which provides conditioned air to up to six FFUs.

Terra can provide custom HVAC modules that operate similarly to an environmental test chamber, adjusting the supply air's temperature and humidity to maintain specific conditions within tight tolerances. This type of system is particularly useful when the environment immediately outside of the cleanroom experiences significant fluctuations in temperature or relative humidity.

G – Environmental Monitoring

(back to chart)

Smart® Fan Filter Power & Control Panels centralize control over assignable groups or specific targets when conducting cleanroom pressure-balancing, troubleshooting, or maintenance. An upgraded Smart Control System allows additional environmental sensors and FFU control to meet critical performance/monitoring requirements. A control panel assembly includes power controls for the Fan/Filter Units, lights, and is configurable for other integrations including temperature, humidity, particle counts, differential pressure, and air velocity sensors.

G1 - Temperature

Terra's thermometers, hygrometers, and data recording instruments help monitor, control, and document environmental conditions in your cleanroom or laboratory. Temperature, dew point, and humidity monitoring are essential for products with known sensitivities to heat, environmental drift, static, or trace moisture. Terra Universal provides decades of field-proven expertise and a wide selection of thermometers and sensors for complete room monitoring.

G2 - Humidity

Many labs and cleanrooms choose to maintain a 30% RH level. Anything more than that may cause other issues, such as damage to moisture-sensitive materials. Every Terra cleanroom is available with integrated sensors and monitoring equipment for measuring and recording relative humidity values within the cleanroom.

G3 - Differential Pressure

Magnehelic® Differential Pressure Gauges monitor room-to-room pressure or filter back-pressure. Digital and alarm models are available for activating alerts when pressures fall out of specification.

G4 - Particle Counting

Particle counters are available as standalone handheld units for spot-checking and validation, or as built-in modules for remote monitoring after connection to a centralized building management system (BMS) such as MODBUS.

H – Ventilation & Contaminate Control

(back to chart)

H1 - False Ceiling Exhaust

False Ceiling Exhaust: Use of a plenum mounted above the drop ceiling to divert air away from the work area. A false ceiling exhaust includes an array of ceiling-mounted reverse flow fan filter units. Reverse fan filter designs remove air from the work environment and port to an outside environment or dedicated HVAC exhaust. Reverse flow fan filter units mount to the ceiling grid and are available with integrated blowers, or with motorless designs for connection to a remote HVAC blower.

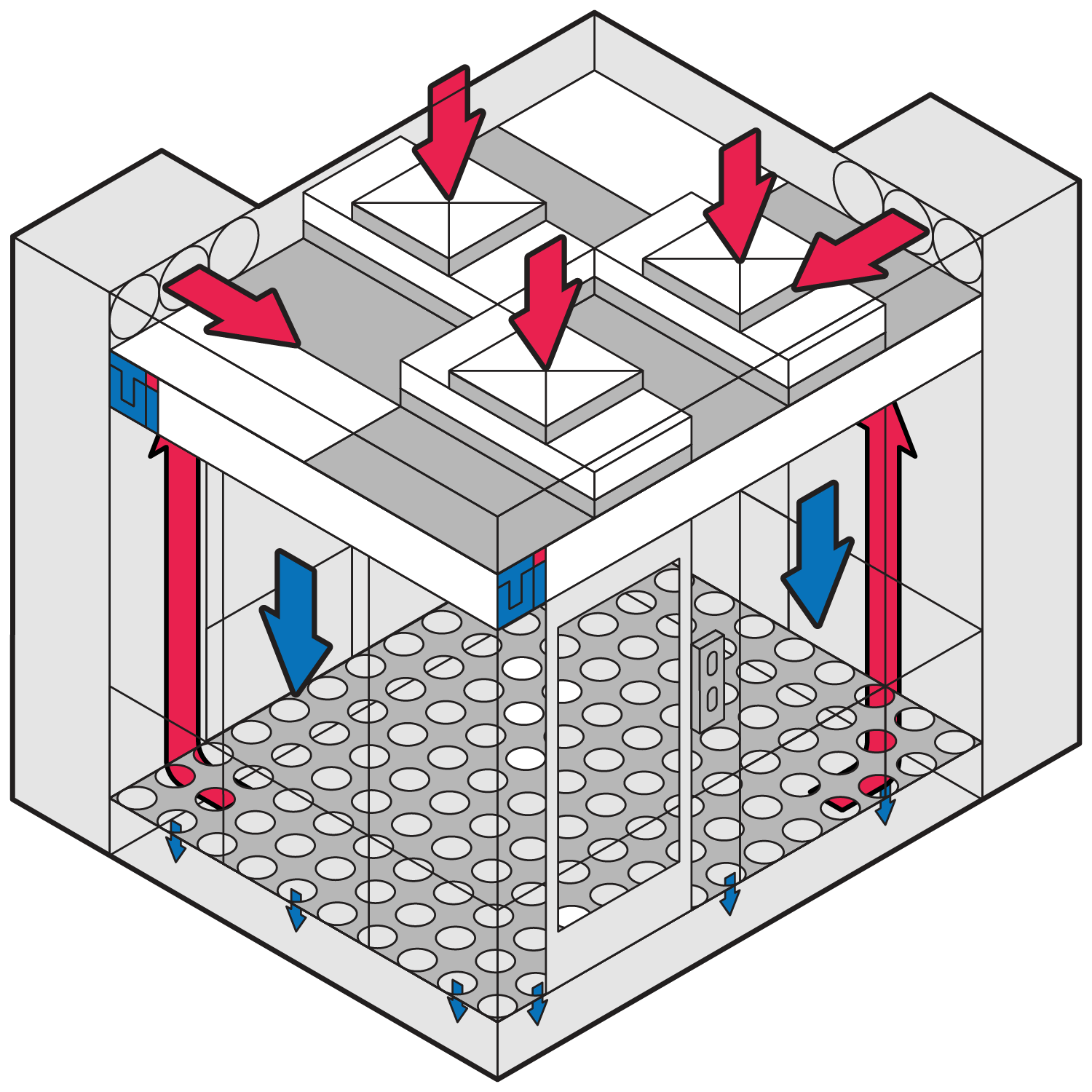

H2 - False Floor Exhaust (Complete Laminarity)

False Floor Exhaust: Raised grated or air-permeable flooring with bottom plenum underneath to achieve full airflow laminarity. False floor exhaust systems, also known as pass through floor exhausts, feature a grated flooring that provides unidirectional airflow and passage of contaminated air. Raised flooring is common for semiconductor applications and ideal for cleanroom classifications below ISO 5 to optimize vertical laminar flow.

H3 - Floor-Mounted Exhaust

Floor-Mounted Exhausts use side-wall plenums and floor-mounted air handlers to divert air away from the work area. The plenum is mounted directly to the frame and connects to ceiling ducts that exhaust air from the negative pressure room. Floor mount exhausts include internal airflow baffles to smooth corner flow and a pass vent at the bottom with an optional fixed position damper. Containment (negative pressure) rooms require customer furnished in-house exhaust systems capable of pulling the air volume required to create adequate negative pressure

h2 - Biosafety Levels I & II

Biosafety Level 1 is specified as work with well-characterized agents that are known to cause disease in healthy, non-immunocompromised adults. Special containment practices and devices are generally not required, but institutional laboratory practices must be implemented to reduce risk to laboratory personnel.

Biosafety Level 2 is specified as work that poses moderate hazards to personnel and the environment. Research or diagnostic activities that are administered with pathogenic bacteria, such as Staphylococcus aureus or Salmonella, fall into this category. This Biosafety Level builds upon Biosafety Level 1; all of the precautions and practices spelled out in Biosafety Level 1 must be followed in addition to those found in Biosafety Level 2. Special containment practices and devices are generally required to mitigate risk to laboratory personnel.

I – Upgraded Features

(back to chart)

I1 - Ion Bars

Ionization bars neutralize electrostatic charges, a common requirement for mixing, packaging, or high-speed assembly lines. Static ionizing bars remove errant charges and have special importance for products with insulative properties.

I2 - Air Curtains

Air curtains produce a jetstream of ULPA Class 10 micro-filtered air at the entry and exit points of a controlled environment. Air curtains are ideal when doors are frequently opened or for doorless entryways. Operating modes include either motion sensor activation with adjustable delay or continuous operation.

I3 - Uninterrupted Power Supply

An uninterrupted power supply (UPS) is only used to maintain power in the cleanroom for a brief time during an unanticipated power outage. A UPS guarantees uninterrupted visibility inside a cleanroom in the event of power loss and provides power for one light (LED or fluorescent) for one hour.

I4 - Cleanroom Emergency Lights

The cleanroom emergency light is an LED light with a backup battery that will remain on during a power outage so employees can see well enough to shut down operations, secure any sensitive products, and evacuate safely in the case that power cannot be immediately restored.

The LED light has a red/green indicator to inform employees after power has returned and the cleanroom is safe to re-enter. When receiving power, the light both operates normally and charges the emergency battery.

I5 - Germicidal UV Lights

UV sanitizing modules affix to the cleanroom ceiling grid to neutralize bacteria, viruses, and mold spores. UV light is particularly effective when targeting resistant bacteria, mold/fungal spores, and gram-negative microbes. The UV-C Germicidal Lamps install on a cleanroom ceiling grid for line-of-sight room disinfection. A safety occupancy sensor switches off the UVC lighting to prevent radiation exposure when occupied.

I6 - Fire Detection System

Terra provides fire detection and suppression systems ideal for wet benches, exhaust fume lines, and locations involving volatile chemicals. Terra cleanrooms support traditional sprinkler and heat sensor configurations or CO2-based suppression systems. The FS System 7 is an integrated fire detection and CO2 suppression system that includes electro-optical sensors for detecting any type of hydrocarbon or non-hydrocarbon fire, even through gas or vapor. A dual-stage alarm triggers an early warning for fires too small to be sensed by overhead sprinklers. An intelligent multi-stage response system prevents the damaging effects of fire suppression in the case that a small fire self-extinguishes or is suppressed rapidly. Terra engineers work with you to determine the fire suppression system appropriate for your requirements and local fire codes.

I7 - Fingerprint Scanner

Biometric fingerprint scanners prevent unauthorized access via shared keys or passwords while also providing data logging capability. An integrated proximity card reader enables two-factor authentication.

I8 - Iris Scanner

Fully automated iris scanner for secure, hands-free access (includes data logging and optional secondary keycard reader).

I9 - Keycard Reader

Keycard readers provide a durable and economical method for maintaining secured keycard access within a cleanroom facility. The low-profile device reads cards up to 3" away and integrates with access control software for data logging and remote monitoring.

I10 - Pass Through

General-Use Pass-Through Chambers are an economical choice for non-sterile items with a low risk of cross-contamination potential including samples, fluids, tools, packaging, or documents.

ValuLine™ Pass-Through Chambers are configurable with economical black acrylic, chemical resistance polypropylene, or stainless steel for unmatched cleanliness and durability within cleanrooms.

BioSafe® Pass-Through chambers with continuous seam welds eliminate hard-to-clean cracks and crevices that can harbor particles and germs. CleanSeam™ design conceals the door interlock mechanism behind the chamber’s wall for a completely unobstructed, easy-to-clean chamber interior.

I11 - Talk Through

Communication and vocal clarity are critical for successful outcomes within cleanrooms, laboratory, and hospital isolation environments. Mechanical and electronic talkthroughs allow easier communication between internal partitions or outside areas of the cleanroom. Both the mechanical and electronic talk throughs include cleanroom-grade components and are easy to mount in either a stick-built cleanroom wall or Terra hardwall modular cleanroom.

I12 - Interlocking Doors

Interlocking doors are common for passthrough chambers and air showers. The interlock prevents doors on either side of the enclosure from opening at the same time. Single side access helps to maintain airflow cascades between rooms of differing pressure and limits room pressure loss after opening and closing of doors.

J – Services

(back to chart)

J1 - Cleanroom Installation

Terra Universal is one of few cleanroom manufacturers to provide in-house engineering, in-house design services, and in-house component manufacturing from a single source. While most contractors rely on external engineering teams for drafting and floorplanning, Terra reduces layers of communications and simplifies facility planning and construction to a single point of contact. If requirements change, our modular design allows you to add filters, lighting, ionization, or additional floor space—all at a fraction of the cost you'd face with other systems.

J2 - White Glove Delivery

Terra Universal provides specialized freight service on a per-project basis. Extended delivery options include inside delivery and delivery after business hours. Terra is committed to ensuring the timely and safe delivery of your product. Terra provides product on-site placement and assembly services for facilities that lack the necessary equipment or expertise during the installation and startup process. Our shipment consolidation services provide our customers extended control over shipment and delivery dates by streamlining pickup and delivery times. In-transit freight consolidation ensures pickup and shipment of items at prespecified times. Items are transported from the factory as needed or held at a consolidation terminal for later delivery to the end destination within a prespecified time window.

J3 - FasTrak Expedited Production

Terra's FasTrak limited guarantee is to ship on or before the date specified or to refund up to 100% of FasTrak charges on the client's approved request. This guarantee does NOT cover direct, special, consequential, or other damages and is strictly limited to 100% of the amount paid for FasTrak service.

J4 - Cleanroom Certification

Terra Universal is the leading expert in the design and fabrication of critical environment applications. Terra offers end-to-end certification and testing services for cleanrooms, hoods, glove box isolators, biosafety cabinets, and lab equipment. Services include HEPA leak testing, airflow velocity, airborne particle counting, room pressurization, airflow visualization, ASHRAE 110, and volatile organic compound testing.

J5 - Cleanroom Equipment Validation (IQ/OQ/PQ)

Terra Universal provides comprehensive, turnkey equipment validation packages on a per-project basis. Contact your Terra Universal product specialist to discuss project-specific requirements with our validation engineering team.

Services include:

- Installation Qualification

- Olierational Qualification

- lierformance Qualification

- Construction Qualification

- Factory Accelitance Testing

- Site Accelitance Testing

- User Requirement Sliecification

- Statement of Work

- Feasibility Study

J6 - Decontamination and Cleaning

The Terra Universal network includes trusted vendors for deep micro-cleaning after commissioning and regular cleaning services on a monthly, weekly, or as-needed basis. Through our critical environment cleaning professionals and the use of innovative technology, we make certain your cleanroom environment meets or exceeds the industry’s highest regulations for contamination control, maintenance and safety. We offer comprehensive decontamination service packages for a multiverse of cleanroom applications, gown rooms, vivariums, biomedical facilities, laboratories, and cold/dry rooms.

J7 - USP <797> Consultation

Terra Universal provides uncompromising informational and consultative support for USP 797 and USP 800 compliance. If applicable, Terra will offer a 60-minute phone call with staff compounding pharmacist (CPHA Policy Committee member) Dr. Chris Munoz. Terra USP compounding suites include (as requested) custom cleanroom drawings outlining dimensions, layout, and placement of HEPA filters.

Due to high demand for this consultation and the scope of service provided, Terra must require an up-front consultation fee that will be applied to the purchase of a Terra USP cleanroom; however, even those who do not purchase from Terra will receive cost-saving guidance far exceeding the price of this bundle.

J8 - Seismic Structural Analysis

Terra’s modular cleanrooms are designed with seismic safety in mind. Rigid steel frames and ceiling grids are designed with sufficient factors of safety to provide vertical and lateral strength recommended by professional engineers. Both hardwall and softwall designs can be installed to adhere to local seismic codes. Optional seismic and structural calculations can be drafted and stamped by a licensed PE to help meet municipal permitting requirements.

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731