What is Lyophilization?

Lyophilization, or freeze drying, is a common technique used in the pharmaceutical and food industries to vacuum freeze samples for long-term, ambient storage.

How Does a Lyophilizer Freeze Dryer Work?

Freeze-drying equipment uses sublimation to remove water, or common solvents such as methanol or acetonitrile, from a pre-frozen product. Sublimation occurs when a frozen aqueous sample moves directly from a solid to a gaseous state, without passing through the liquid phase.

Advantages of Lyophilization

By avoiding the liquid phase, the process of sublimation ensures the yield of a stable product that can be stored outside of a freezer and reconstituted for processing years into the future.

Continue: Advantages of Lyophilization for Long-Term Sample Storage

Pharmaceutical and Biotechnology Lyophilizer Applications Include:

- Manufacturing Active Pharmaceutical Product Ingredients (APIs)

- Increase shelf life of pharmaceuticals, vaccines, and lab samples

- Parenteral formulations and injections

- Increase stability of therapeutic proteins (monoclonal antibodies)

- Freeze drying for long term storage of dry powder with live microorganisms (probiotics / bacteria)

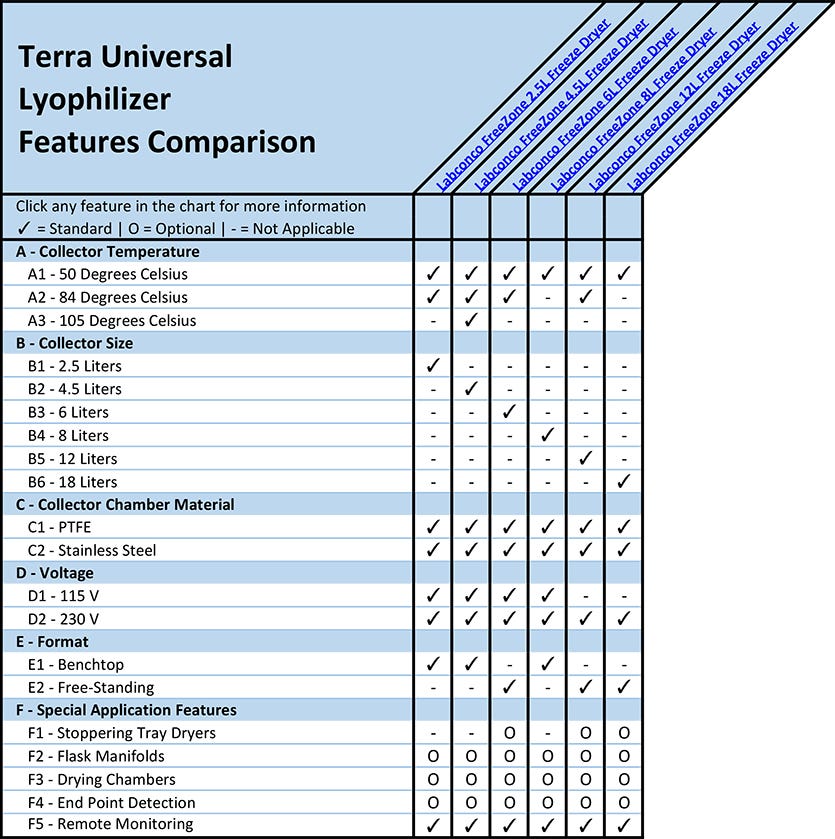

A - Lyophilizer Collector Coil Temperature

(back to chart)

The lyophilizer collector coil acts as a cold trap to collect moisture vapor eluting from the frozen product. To ensure the effective capture of sample vapor during sublimation, the collection coil must maintain a temperature of 15 – 20 degrees colder than the sample’s freezing point.

Aqueous Only

Freeze dry systems for aqueous samples have a working temperature of -50°C. Benchtop and console Lyophilizers are available in a range of capacities.

Low Eutectic Point

Freeze dry systems for low eutectic point samples have a working temperature of -86°C. Benchtop and console Lyophilizers are available in a range of capacities.

(Optional: Solvent & Collector Freezing Points: Table Shown Here)

A1 - 50 Degrees Celsius Lyophilizer Dry Freezers

A collector coil cooling to -50 degrees is optimal for freeze drying aqueous samples stored in DI or nuclease-free water.

View Price: FreeZone 18 Liter -50C Console Freeze Dryers by Labconco

A2 - 84 Degrees Celsius Lyophilizer Dry Freezers

A collector coil cooling to -84 degrees is ideal for low eutectic point samples stored in DI water or acetonitrile.

View Price: FreeZone 2.5 Liter -84C Benchtop Freeze Dryers

A3 - 105 Degrees Celsius Lyophilizer Dry Freezers

A collector coil cooling to -105 degrees is optimal for low eutectic point samples stored in methanol or ethanol.

B - Lyophilizer Collector Size (Capacity)

(back to chart)

The collector size lists the ice holding capacity, in liters, housed by the system during a single run. The maximum sample volume, per session, is 50% of the ice holding capacity.

Benchtop systems with capacities of 2.5 liters, 4.5 liters, and 8 liters are optimal for light to moderate sample loads.

Free-standing systems, with 6-liter, 12-liter, and 18-liter capacities are appropriate for large sample loads or numerous batches.

Browse Lyophilizers by Ice Holding Capacity

C - Lyophilizer Collector Chamber Material

(back to chart)

C1 - PTFE Lyophilization Chamber

PTFE-Coated Collector Coils and Chambers are recommended for lyophilization processes involving corrosive compounds.

C1 - Stainless Steel Lyophilizer Chamber

Stainless steel Lyophilizer Chambers and Collector Coils are optimal for lyophilization processes involving non-corrosive compounds.

F - Lyophilizer Bulk Trays, Flasks, Tubes and Accessories

(back to chart)

F1 - Lyophilizer Stoppering Tray Dryers

Labconco Stoppering Tray Dryers are ideal for batch drying operations involving pre-frozen samples from the same, or similar, production lot; the vessels are placed in a tray dryer to ensure uniform conditions. Although slight variations in drying conditions may be experienced for samples located near the clear front door of the tray dryer, the samples are heated under the same protocol and conditions to ensure maximum uniformity.

View: Labconco Freezone Stoppering Tray Dryers

F2 - Lyophilizer Freeze Dryer Flask Manifolds

Manifold drying provides a flexible alternative to tray drying for small volume samples with high eutectic and collapsed temperatures, vials, ampules, or frost-free flasks. Manifolds are connected to individual ports on the manifold after the pre-frozen samples are removed from a storage freezer or low-temperature water bath. Manifold systems accommodate vessels of different sizes to allow drying of multiple products or batches during a single run. As each vessel has a direct connection to the collector, manifold drying is more efficient than tray drying.

Compare: Purge Valve | Mini Chamber Purge Valve

F3 - Bulk Lyophilizer Freeze Drying Chambers

For stable products resistant to changes in moisture or oxygen levels, bulk drying chambers permit precise control of temperature and heat input. Rather than drying products sealed in individual vessels, bulk drying involves spreading the products across the surface area of a shelf or tray. As heat is transferred to the samples through conduction from the shelf or tray, the product must be spread across the area to a uniform thickness to prevent changes in heating rates. Bulk drying is not suitable for samples prone to cross-contamination or changes in atmospheric conditions.

Lyophilizer Chamber Sizes and Dimensions:

- 2.5L Lyophilization Chambers

- 4.5L Lyophilization Chambers

- 6.0L Lyophilization Chambers

- 12L Lyophilization Chambers

F4 - Lyophilizer End Point Detection

Determining the primary drying end point for each sample can be a challenge. Once the vessel is free of ice residue, the drying of samples located at the edge of the container is complete. To ensure that the center of the product has completed the drying process, an electronic vacuum gauge is used to measure the condensable gasses in the closed system. When the electronic gauge displays a pressure equal to the minimum level attainable by the system, the sample contains no more water vapor.

Labconco Freeze Dryers

Labconco’s End Zone system provides an alert when sample moisture levels have reached user-selected criteria, taking all of the guesswork out of end point determination.

Labconco’s Lyo-Works operating system, included on each FreeZone model, provides an audible alarm and automated email to each user when sample end points are reached.

Compare Online: Labconco Free Dryer Pricing

F5 - Lyophilization Remote Monitoring Dry Freezer Conditions

While freeze drying runs can extend well beyond normal working hours, remote system monitoring is crucial to ensure system efficiency. Labconco’s Lyo-Works operating system, standard on all FreeZone models, provides users with real-time sample conditions, including vacuum levels and collector temperature. Sample status updates are provided by email to each selected user when runs are completed, the drying end point is determined, and system parameters change.

Lyophilizer Setup and Installation

https://www.youtube.com/watch?v=eHy_pB8GIwg

Where Can I Buy a Lyophilizer Dry Freezer?

Laboratory-Equipment.com offers carefully selected lines of Labconco dry freezers. Through our worldwide network of reps, we supply some of the largest research and production facilities in the world. Laboratory-Equipment.com is a laboratory speciality division of Terra Universal. For nearly 40 years, Terra has served semiconductor, aerospace, life science, pharmaceutical, biotechnology, and medical device markets.

Contact a Laboratory Equipment Specialist for assistance with technical questions, consultative sales, and selection and configuration of a product to fit your needs. Representatives are available Mon - Fri, 09:00 AM - 08:00 PM your local time, via phone, email, or live web chat.