Did You Know?

Fan/Filter Units Do More Than Meet ISO Requirements—they also prevent infection.

Most cleanroom professionals understand that FFUs capture contaminants that degrade particle-sensitive samples. But they also remove bacteria and many viruses and mold spores that contribute to a host of infections.

Most common bacteria are contained by the 0.3-micron pore size of high-efficiency particular air (HEPA) filters. Ultra-Low Penetration Air (ULPA) filters, which are rated 99.999% efficient at retaining particles of 0.12 microns and larger in diameter, capture ultra-fine contaminants, including many large viruses and mold spores.

These filters also remove aerosol-born pathogens—germs that literally hitch a ride on larger particles and liquid droplets that are captured in a HEPA or ULPA filter.

HEPA- or ULPA-based Fan/Filter Units (FFUs) thus can play an important role in infection prevention in surgical theaters, ICUs and other medical settings. Here is a list of common human pathogens that HEPA/ULPA filters capture and remove from circulation:

- Escherichia coli: Gastrointestinal infection

- Bacillus anthracis: Anthrax

- Aspergillus brasiliensis: Sinus infections

- Francisella tularensis: Tularemia

- Bordetella pertusis: Whooping cough

- Mycoplasma pneumaoniae: Pneumonia

- Chlamydia pneumoniae: Bronchitis

- Clamydia psittaci: Psittacosis

- Klebsiella pneumoniae: Opportunistic infections

- Haemophilus influenzae: Meningitis

- Coxiella burnetii: Q fever

- Pseudomonas aeruginosa: Opportunistic infections

- Actinomyces israelii: Actinomycosis

- Legionella pneumophila: Legionaire's disease

- Thermoactinomyces sacchari: Farmer's lung

- Alkaligenes: Opportunistic infections

- Streptococcus pyogenes: Scarlet fever

- Mycobacterium Tuberculosis: Tuberculosis

WARNING:

Don't underestimate the importance of uniform airflow!

ISO, FDA or cGMP laminar flow requirements necessitate uniform airflow velocity across the filter face of fan/filter units (FFUs). Many FFUs that appear to meet nominal cleanliness requirements fail to provide this uniformity, threatening the integrity of your clean processes.

What is airflow uniformity?

Certifiers measure air velocity at multiple (typically six or eight) locations across a filter face. Ideally, air speed measurements taken at these locations vary by no more than 15% from mean values. For example, in an ISO 5 laminar flow system with a specified minimum average air velocity of 90 fpm (feet per minute), the minimum air speed measurements typically should be in the range of 80 – 100 fpm.

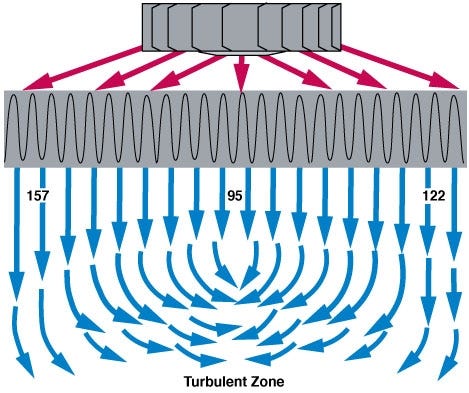

Discrepancies greater than this create turbulence as the faster air streams (lamina) are drawn into the localized areas of lower pressure created by the slower ones.

The greater the airspeed differential, the more likely and the more severe this turbulence becomes, resulting in swirling that can suspend minute particles rather than sweeping them downward and out of the laminar flow system. Worse, localized turbulence can create second-pass air that swirls up and re-enters the downward flow, drawing particles upward and redistributing them into other locations inside the classified work space. Under such conditions, a cleanroom or laminar flow cabinet fails to meet ISO laminar flow conditions – and ceases to be a clean!

How does airflow uniformity differ from airflow average?

Some FFU manufacturers specify an average airflow (or average velocity) that can mask serious performance deficiencies.

In the case below, a Fan/Filter Unit produces an average airflow of 1004 CFM (cubic feet per minute) and average air speed of 125 fpm on high speed, perfectly acceptable performance values. However, individual lamina measurements demonstrate substantially non-uniform filter face velocity and flow, with discrepancies of over 60% at various locations across the filter (30% from mean values). FFU performance will create areas of turbulence due to this lack of uniformity.

How does a Fan/Filter Unit achieve airflow uniformity?

Several design and construction features help to ensure uniform FFU performance in Terra-manufactured FFUs. Most importantly, these FFUs include an internal baffling system and plenum chamber that equalize the air pressure across the filter face as the air exits the motorized impeller. Uniform inlet pressure correlates to uniform exit velocity, assuming a high-quality filter medium of uniform density and flow resistance.

In addition, Terra FFUs include a perforated anodized aluminum exit plate that both protects the filter medium against damage and helps to reinforce even air distribution across the filter face.

Finally, sound-deadening foam contributes to the rigidity of the structure while dampening noise and vibration, resulting in whisper-quiet operation that won’t interfere with operator health or productivity.

Although these measures add to the manufacturing cost of Terra FFUs, they contribute substantially to their performance (see comparative data below).

Turbulent Performance: Fan/Filter Unit with non-uniform airflow

Measurements of non-baffled 2' x 4' HEPA Fan/Filter Unit with AC impellerized motor, taken 6" from filter face (source: measurements taken on Terra competitor 2' x 4' HEPA FFU)

High Speed

- Noise: 73 dBA

- Average Speed: 125.5 fpm

- Average Flow: 1004 cfm

- Max. Deviation from Mean: 27.5%

- Top Left: 157 fpm

- Top Center: 95 fpm

- Top Right: 122 fpm

- Bottom Left: 160 fpm

- Bottom Center: 109 fpm

- Bottom Right: 110 fpm

Medium Speed

- Noise: 60 dBA

- Average Speed: 48.7 fpm

- Average Flow: 389 cfm

- Max. Deviation from Mean: 30%

- Top Left: 58 fpm

- Top Center: 47 fpm

- Top Right: 53 fpm

- Bottom Left : 61 fpm

- Bottom Center: 39 fpm

- Bottom Right: 34 fpm

Low Speed

- Noise: 55 dBA

- Average Speed: 7.6 fpm

- Average Flow: 61 cfm

- Max. Deviation from Mean: Out of Spec

- Top Left: 0 fpm

- Top Center: 0 fpm

- Top Right: 0 fpm

- Bottom Left: 46 fpm

- Bottom Center: 0 fpm

- Bottom Right: 0 fpm

Laminar Performance: Terra Fan/Filter Unit with uniform airflow

Measurements Terra’s 2' x 4' HEPA Fan/Filter Unit (No. 6601-24-H) with AC impellerized motor, taken 6" from filter faceHigh Speed

- Speed Setting: High

- Noise: 55 dBA

- Average Speed: 139 fpm

- Average Flow: 980 cfm

- Max. Deviation from Mean: 13%

- Top Left: 150 fpm

- Top Center: 125 fpm

- Top Right: 149 fpm

- Bottom Left: 137 fpm

- Bottom Center: 121 fpm

- Bottom Right: 154 fpm

Medium Speed

- Speed Setting: Medium

- Noise: 54 dBA

- Average Speed: 117 fpm

- Average Flow: 823 cfm

- Max. Deviation from Mean: 12%

- Top Left: 131 fpm

- Top Center: 120 fpm

- Top Right: 111 fpm

- Bottom Left: 121 fpm

- Bottom Center: 108 fpm

- Bottom Right: 112 fpm

Low Speed

- Speed Setting: Low

- Noise: 55 dBA

- Average Speed: 100 fpm

- Average Flow: 703 cfm

- Max. Deviation from Mean: 5%

- Top Left: 105 fpm

- Top Center: 96 fpm

- Top Right: 103 fpm

- Bottom Left: 98 fpm

- Bottom Center: 96 fpm

- Bottom Right: 105 fpm

Specifications

- Dimensions: See Replacement Filter chart

- Housing: Plenum is cold rolled steel finished with white powder baked enamel. Compatible with 1-1/2" (38 mm) grid on 24" x 48" (610 mm x 1219 mm) centers or 2" (51 mm) grid on 24.5" x 48.5" (622 mm x 1232 mm) centers. 304 stainless steel is available

- HEPA Filter: HEPA filter is 99.99% efficient on removal of particles 0.3 microns and larger by DOP (dioctyl phthalate) test. Filter module must be removed from the ceiling for HEPA filter replacement

- Prefilter: 20" x 20" x 1" (508 mm x 508 mm x 25 mm)– UL classified for Class 1; rated 80% efficient on linty dusts

- Blower: Forward curved centrifugal type factory balanced. Entire motor/blower assembly is removable from top of housing for service

- Motor: 1/4 HP Direct drive, energy efficient. Permanent split capacitor type. Thermally protected with automatic overload reset

- Electrical: 3-setting motor switch (lo-med-hi). Motor leads are wired to a cable with Mencom 4-pin connector for field connection to Terra cleanrooms and hoods; specify other required power cable

- Face Grille: Face grille perforated anodized aluminum

- Noise Level: 50 dBA

- Weight: See ordering charts

- Support: 1/4" (6 mm) eyebolts are installed in all (4) corners for hangwire support