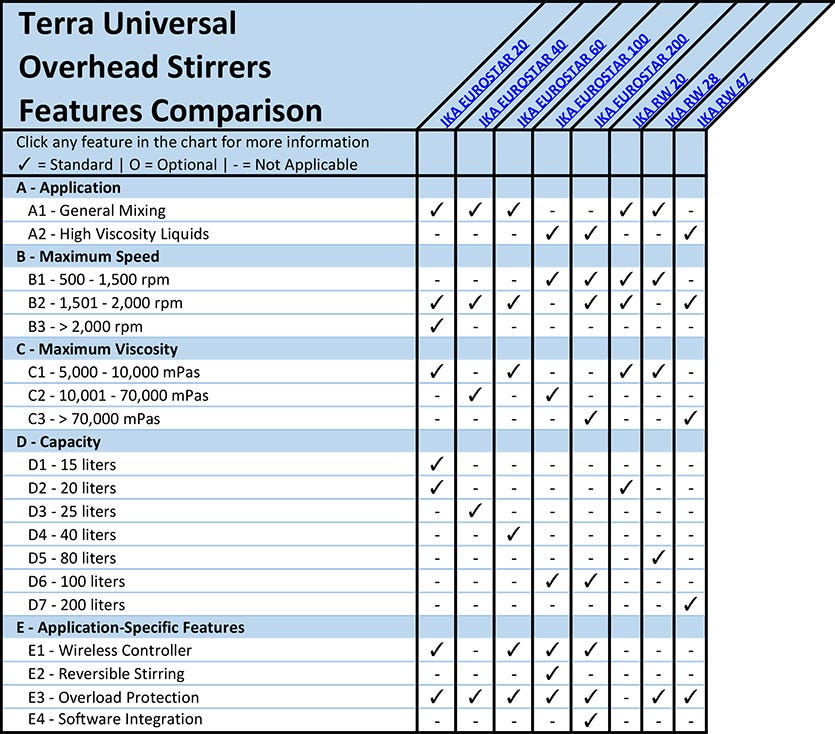

Laboratory Stirrers Comparison Chart

Overhead stirrers consist of a stirring fixture, or stand, a digital controller, a drive shaft, and a motor for mixing viscous solutions. Overhead stirrers are used for a broad range of mixing applications including tissue grinding, cell media preparation, wastewater purification, formulation of polymers, adhesives, and coatings.

Optional lab stirrer accessories include propeller blades, dissolvers, head clamps, manual chucks, telescoping stands, and shaft protectors.

Factory-fitted quick adapters, or chucks, support quick shaft replacement for labs processing a wide range of sample viscosities.

Digital controllers include programmable functions, overload protection alarms, mixing speed adjustment, data export and third-party software integration.

A - Application

(back to chart)

A1 - General Mixing

General overhead mixing stirrers, such as the IKA EUROSTAR 40 models, are ideal for mixing low viscosity liquids below 7,000 mPas (millipascal-seconds). Applications include cell media preparation or soft tissue grinding for drug development.

A2 - High Viscosity Liquids

High-viscosity overhead stirrers, like IKA’s EUROSTAR 100, include interchangeable blades and drive shafts to ensure thorough stirring or homogenization. Ideal for mixing solutions above 7,000 mPas (millipascal-seconds), such as polymers, plastics, adhesives, glues and coatings.

B - Maximum Speed

(back to chart)

Listed in revolutions per minute (rpm), standard overhead stirrers carry a user-adjustable mixing speed range between 30 – 1,500 rpm. However, high-speed models, such as IKA’s EUROSTAR 20, maintain speeds up to 2,000 rpm for low-volume mixing (under 15 ml).

C - Maximum Viscosity

(back to chart)

Max-viscosity stirrers, like IKA’s EUROSTAR 200, are designed to mix solutions up to 150,000 mPas. The dynamic viscosity, reported in millipascal-seconds (mPas), refers to the thickness of the fluid during mixing. As batch solutions may increase in viscosity during the stirring process, the maximum viscosity specification of the overhead stirrer must meet or exceed the highest attainable dynamic viscosity of the solution.

D - Lab Stirrer Capacity

(back to chart)

Capacity refers to the maximum volume of fluid, reported in liters, safely and effectively mixed by the overhead stirrer. Unless otherwise noted in the manufacturer specifications, the maximum volume assumes the liquid to be water.

High-volume overhead stirrers, like IKA’s RW47, are designed to homogenize up to 200 liters of fluid.

E - Application-Specific Lab Stirrer Features

(back to chart)

E1 - Wireless Lab Stirrer Controller

IKA’s EUROSTAR overhead stirrers include a wireless digital controller featuring automatic speed adjustment, programmable functions, multilingual display, timed interval operation, lock/unlock modes, and integrated temperature measurement.

E2 - Reversible Stirring

Reversible stirring models, like IKA’s EUROSTAR 100, are designed to rotate the stirring shaft in clockwise (standard) and counter-clockwise (reversible) directions. For highly-viscous solutions, reversible stirring ensures the fluid is thoroughly mixed.

E3 - Lab Stirrer Overload Protection

Stirrers with overload or overheat protection, like IKA’s EUROSTAR 60, automatically shut down if conditions fall outside of the operating range. Overload protection guards the motor and electronics from heat-related damage during continuous-duty mixing.

E4 - Lab Stirrer Software Integration

Digital overhead stirrers, like IKA’s EUROSTAR 200, include controllers with data export functions compatible with third-party software, such as laboratory information management systems (LIMS). Password-protected profiles and secure data export operations are optimal for cGMP facilities.

Where Can I Buy Laboratory Stirrers and Shakers Online?

Laboratory-Equipment.com is a specialty division of Terra Universal. For nearly 40 years, Terra Universal has served semiconductor, aerospace, life science, pharmaceutical, biotechnology, and medical device markets. Customers appreciate a worldwide network of reps, factory-direct support, and ready-to-ship items available from Terra's manufacturing and warehouse facilities in Fullerton, California.

Shop online to compare pricing, features, and selection for a wide variety of lab stirrer and shaker equipment for applications including general laboratory, PCR, DNA/RNA techniques, ELISA, protein analysis, and cell culture.