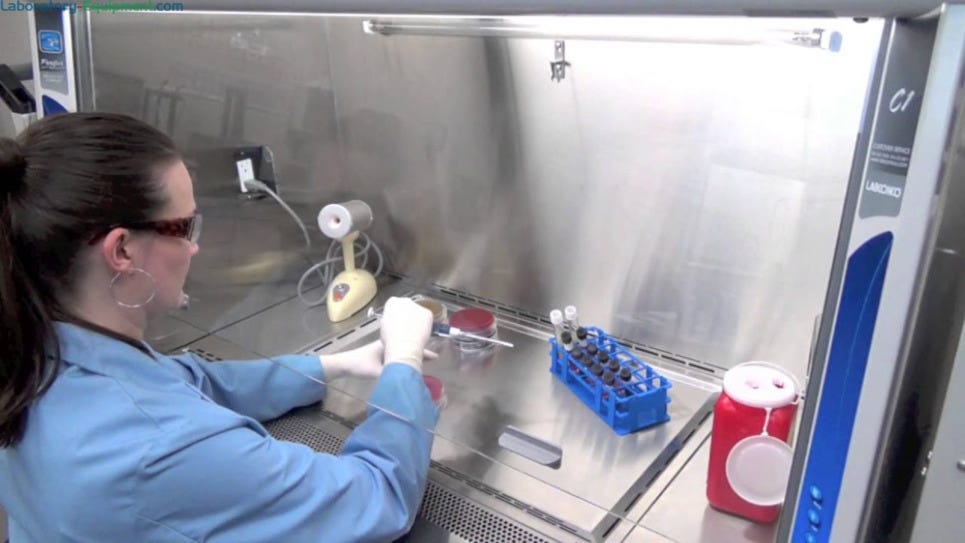

- ADA compliant 4’ Purifier Axiom C1 BSC with OmniFlex Type A2 and B2 modes

- For Biosafety Level (BSL) 1, 2, and 3 containment or BSL 4 with PPE

- Intuitive MyLogic Operating System shows clear status information on LCD display

- Chem-Zone work surface provides operator safety when working with hazardous vapors

- Included: base stand and built-in options (UV light, Vacu-Pass portal and service fixture)

• Model: Purifier Axiom

• Width: 48"

• Biosafety Class: Class II C1

• UV Lamp: Included

• Base Stand: Included

• Manufactured by: Labconco

• Sash Opening: 10"

• Manufacturer SKU: 304411101

• Unit of Measure: EA