On a tight schedule? Choose FasTrak 24/7 Priority Service to help meet your critical schedule for Terra-manufactured products, either before or after your order is placed.*

- FasTrak 24/7 provides a 24/7 commitment to meet the shipping date YOU specify, regardless of quoted lead times.

- FasTrak 24/7 assigns a dedicated production team plus a dedicated senior expeditor working three shifts to meet your delivery specification.

- FasTrak 24/7 guarantees* to meet the agreed-to specified ship date.

Call for pricing. FasTrak service fees cover costs of additional services only, without additional profit.

* Terra's FasTrak services limited guarantee: to ship on the ESD or date specified OR to refund up to 100% of FasTrak charges. This guarantee covers no direct, special, consequential or other damages and is strictly limited to up to 100% of the amount paid for FasTrak service. When a specified ship date is missed due to factors outside Terra's control (vendor performance, deliveries by shipping companies, etc.) and random factors such as accidents, the credit of up to 100% of the FasTrak 24/7 may not apply. FasTrak service requested after order placement will be quoted and accepted based on available time remaining before required ship date.

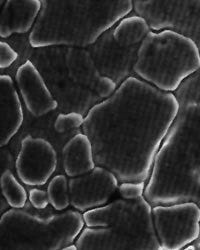

This photomicrograph represents the surface of 304 stainless steel with a No. 2B mill finish before Electropolishing. Note that the etched boundaries between the grains are only partially sealed, resulting in a network of sub-surface crevices. Contaminants that lodge in these crevices are protected from contact with cleaning agents leading to subsequent migration of trapped contaminants onto the cleaned surface.

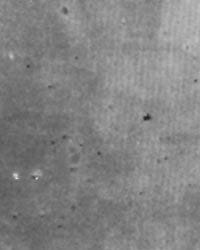

This photomicrograph represents the surface of 304 stainless steel with a No. 2B mill finish before Electropolishing. Note that the etched boundaries between the grains are only partially sealed, resulting in a network of sub-surface crevices. Contaminants that lodge in these crevices are protected from contact with cleaning agents leading to subsequent migration of trapped contaminants onto the cleaned surface. This photomicrograph represents the same No. 2B surface after Electropolishing. Note that the surface is now completely featureless on a microscopic level and has the desired noncontaminating, non-particulating and non-sticking properties.

This photomicrograph represents the same No. 2B surface after Electropolishing. Note that the surface is now completely featureless on a microscopic level and has the desired noncontaminating, non-particulating and non-sticking properties. This photomicrograph represents a 304 stainless steel surface with a mechanically polished No. 4 mill finish before Electropolishing. Note the deep grooves, cavities, torn metal and other microscopic imperfections that entrap and retain contaminants.

This photomicrograph represents a 304 stainless steel surface with a mechanically polished No. 4 mill finish before Electropolishing. Note the deep grooves, cavities, torn metal and other microscopic imperfections that entrap and retain contaminants. This photomicrograph represents the same No. 4 finish after Electropolishing. The surface may still show some of the abrasiveproduced topography to the naked eye, but will now be microscopically featureless with the desired non-contaminating, non particulating and non-sticking properties.

This photomicrograph represents the same No. 4 finish after Electropolishing. The surface may still show some of the abrasiveproduced topography to the naked eye, but will now be microscopically featureless with the desired non-contaminating, non particulating and non-sticking properties.