A HEPA fan filter unit (FFU) is a crucial component of every cleanroom environment. Making the correct decision as to which type of FFU is the most appropriate for your application is not something to simply gloss over. There are two main categories of motorized fan filter units: permanent split capacitors (PSC) and electronically commutated motors (ECM). Both types of fan filter modules provide a perfunctory standard for any cleanroom, but differ by way of efficiency, durability and cost. PSC systems save you money upfront and are ideal for small, consistent projects. However, when considering longer endeavors, especially those with ever-changing circumstances, the ECM will pay for itself with energy savings. For instance, in California at an average of 14.47 cents per kilowatt hour, you would make the difference between the higher upfront costs of the ECM over the PSC back in a year, and profit every hour of use after that.

Power Consumption (watts)

Consider the light-bulb market as it stands today; big box retailers advertise low-cost incandescent, high wattage bulbs, yet LED bulbs create the same illumination while using 6-times less energy at a higher upfront cost. The same implication holds true with cleanroom filter fan units in the divide between ECM and PSC motors. Units are separated by upfront versus long-term costs as well as simplicity and capability. The breakdown below illustrates the savings:

| Motor Type | Low Speed | Medium Speed | High Speed |

|---|---|---|---|

| PSC motor | 365W | 380W | 430W |

| EC motor | 90W | 168W | 350W |

Cost Saving Comparison

| FFU Type | Unit Cost | Annual Energy Cost | Lifetime Energy Cost | Lifetime Dollar Savings |

|---|---|---|---|---|

| Standard FFU (PSC motor) | $776 | $430 | $4,800 | 0 |

| Smart FFU (EC motor) | $1,089 | $127 | $1,414 | $3,386 |

| *Operating time: 24 hours a day, 7 days a week *5 days a week on medium speed for 8 hours and low speed for 16 hours *2 days a week on low speed for 24 hours *Energy Cost: $0.14/kWh *Operating life: 90,000 hours |

||||

Benefits of FFUs with PSC motors

Terra’s WhisperFlow® cleanroom fan filter units with PSC motors offer a simple solution for low-need operations, namely small-scale projects. They provide an overall low upfront purchase costs and ease of operation for most cleanroom environments. These fan powered hepa filters can be installed with a simple remote switch—no network programming required. Although PSC motors are capable of multiple speed settings, they’re only optimized for peak efficiency on high settings. Medium and low settings demonstrate a noticeable drop in effectiveness. Consider a small gowning room, where 400 cubic feet per minute (CFM) of airflow is required—a PSC motorized HEPA filter module on low speed would provide approximately 600 CFM, expending unnecessary resources. The typical service-life of a properly maintained PSC unit conservatively spans 50,000 hours of use.

Given the ease of use and ability to “plug’n’play,” PSC motors remain the easiest choice for fast installation, without the necessary downtime of waiting for system integration. It seems like the simplicity of PSC motors would suit any basic cleanroom FFU system, but “airing” on the side of caution—is there a better way?

Benefits of FFUs with EC motors

Terra’s Smart® WhisperFlow® energy efficient FFU with EC motors offer a wide breadth of cost-saving cleanroom solutions, from its efficient design, to advanced settings that exhibit lower A-weighted decibels (dBA) registering 40 dBA at medium settings, low vibration, precision and energy-savings. ECM hepa filter blowers demonstrate a 50% reduction in power consumption compared to the standard PSC units when running both units at 90 feet per minute face velocity. Taking this reduction into account, the ECM FFU cost-savings add up quickly, and with less required maintenance, expensive downtimes typical of PSC systems will not hinder cleanroom operations. ECMs utilize a back-pressure monitoring system to alter fan speed to accommodate obstructions stemming from filter saturation—the ECM will continue to operate effectively, whereas the PSC motor will lose effectiveness as the saturation level increases.

These energy efficient FFUs demonstrate a service-life exceeding 90,000 hours, close to double that of PSC units. Terra’s smart motors reduce the risk of costly down-time due to an unexpected FFU failure. Additionally, with the reduction in energy costs, you can earn Leadership in Energy and Environmental Design (LEED) points for your cleanroom set-up, further driving down operational costs.

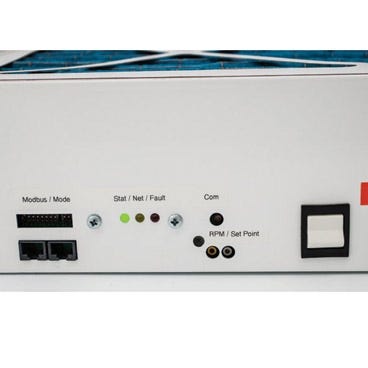

ECM FFU systems utilize an FFU control system and can be programmed to compensate for shifts in air pressure—something as simple as opening a cleanroom door can drastically change the working environment—increasing or decreasing fan movement speeds to align. The same energy-savings can be applied to low demand times as with situations that require even less energy-use than what’s available with PSC units—again, wattage would simply be wasted and resources consumed.

ECM vs. PSC FFU Energy Efficiency

You could simply look at the price-tag of a product and assume its low-cost based on the figure, but as you have seen, this premise is often misleading. Take the light-bulb analogy—it’s important to understand the cost of usage over that of the upfront price of the bulb—otherwise in the long run, with heavy use, you will certainly waste resources. Notice the service-life of incandescent and LED bulbs, 10,000 versus 50,000 hours respectively; the operational divide between the two remains daunting from a cost-benefits standpoint. The same anchor point holds when comparing ECM and PSC FFU systems.