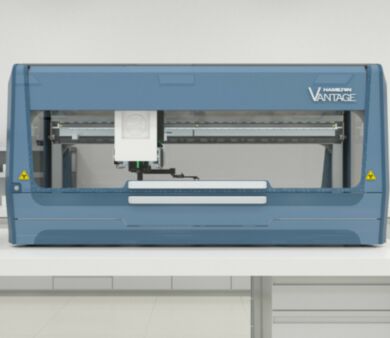

- Compact Microlab VANTAGE Automated Liquid Handler available in 1.3 and 2.0 models ideal for low pipetting volumes

- Modular design with enhanced performance enables instrument upgrade for application flexibility

- Configuration options: pipettor, logistics cabinet, track gripper and rear integration cabinet (contact our sales representative for details

- Enables device integration, allows different users to run various assays on the same instrument and increases walk away time

- Capacity from 96- to 384-well plates or partial plates

Microlab VANTAGE Automated Liquid Handlers available in 1.3 and 2.0 models with options for pipette channels, integrated cabinets, arms and transport devices | 1017-PP-05 displayed

Liquid Handlers & Robotics

1017-PP-05

1017-PP-05 80050

Microlab VANTAGE Automated Liquid Handling Platform by Hamilton Robotics

Read more

Manufactured By: Hamilton

Print

Want a quote quickly ?

Submit a QuickQuote request

Select Product Options

Summary

- Compact Microlab VANTAGE Automated Liquid Handler available in 1.3 and 2.0 models ideal for low pipetting volumes

- Modular design with enhanced performance enables instrument upgrade for application flexibility

- • Configuration options: pipettor, logistics cabinet, track gripper and rear integration cabinet (contact our sales representative for details

- Enables device integration, allows different users to run various assays on the same instrument and increases walk away time

- Capacity from 96- to 384-well plates or partial plates

- Optional features (sold separately):

- Pipetting arm holds pipetting devices, camera and transportation devices

- Logistics cabinet houses 3rd-party devices, labware and consumables

- Track Gripper allows parallel movement of pipetting and labware

- Internal Plate Gripper transports labware to various locations on the pipetting workspace

- Design Features:

- Multi-Probe Head (MPH) enables pipetting of 96- to 384-well plates or partial plates

- Identification Loading Device (DL) detects and scans 10 to 20 labware barcodes

- NanoPulse channels offer a dynamic range of 0.5 μL in Jet Mode up to 1000 μL within a single channel

- Enables placement and configuration of carriers, tips and waste products on workspace for application flexibility

- Multi-colored status light

- Graphical drag and drop programming interface turns lab protocols into automated assays

- Sensor-controlled enclosure safeguards users and protocols

- Storage capacity of up to three EntryExit modules enables unattended runs

- Separated waste compartments for biohazard and non-biohazard solid and liquid waste

- Instinct V Software Features:

- SLA compliant software architecture enables third-party device exchange

- Enables multiple users to run different assays on the same instrument

- Graphical drag and drop programming

- XSL Assay Editor for complex demands and Workflow Editor arranges multiple assays

- Enables remote status monitoring with smart device

- CARE (Contamination Avoidance Response) provides notification in event of contamination

- Intuitive navigation and streamlined dashboard design

- Dynamic Scheduler finds the most efficient assay run and enables users to add assays to workflows

- User management allows set up of up to 60 different privileges to accounts and roles to meet all restrictions

- Automatically generates transportation steps and tracks starting position to final destination

- Multiple, definable error recovery keeps assay running with manual, semi-automated or walk-away options

- Reduced set-up time and optimized runs with 3D run visualization with adjustable speeds via a desktop computer prior to actual assay

- Security: enclosed housing with sensor control protects users, multiple optimization system guarantees safe process, database software prevents data manipulation, safeguards samples by notifying user in event of needed intervention

- Automatic population of most values required

- Operating Conditions:

- Temperature Range 15ºC – 30ºC

- Operating Humidity 15% – 85% (no condensation, indoors)

- Electrical Power Requirements 110-230V AC 50/60Hz +-5%

- Operating Altitude up to 2000 m / 6561 ft. above sea level

Specifications

Helena

Other products you may find relevant