Learn More: W.A.T.E.R. Analysis Program

W.A.T.E.R. Analysis Program

- Free water analysis program

- Eliminate the variables and make the best choice for a water system

- Determine operating cost of the proposed system

Your water system purchase should be based on facts, not guesses or estimations. That’s why we offer the W.A.T.E.R. testing program to analyze your water needs before you purchase anything. Not all water systems are created equal. Some system cartridges have less capacity than others, meaning an increased operating cost for you. We’ll not only analyze your water and recommend a system, but we’ll tell you what your annual operating costs will be with that system.

Here’s How the W.A.T.E.R. Analysis Program Works:

- Contact Terra Universal for a free W.A.T.E.R. test kit

- Fill the sample bottle with water from your anticipated feed water

- Fill out the short questionnaire pertaining to your water requirements, applications and budget

- Place the completed application and water sample bottle in the return box. Add postage and mail to the Water Lab at Thermo Scientific

- Our team of water experts will perform different tests on your sample, including TOC, conductivity, resistivity and total ionized particles

- Upon evaluation, your water test results will be matched with your laboratory requirements listed on the questionnaire

- A water system will be recommended based on our water evaluation and the responses on your questionnaire

- We will determine annual operating costs for the system based on your usage and feed water test results

- The test results, equipment recommendation, operating cost and quotation will be mailed directly to you

- At no obligation to you, we will have a representative call you to discuss your customized report and help you finalize any details with regard to your system

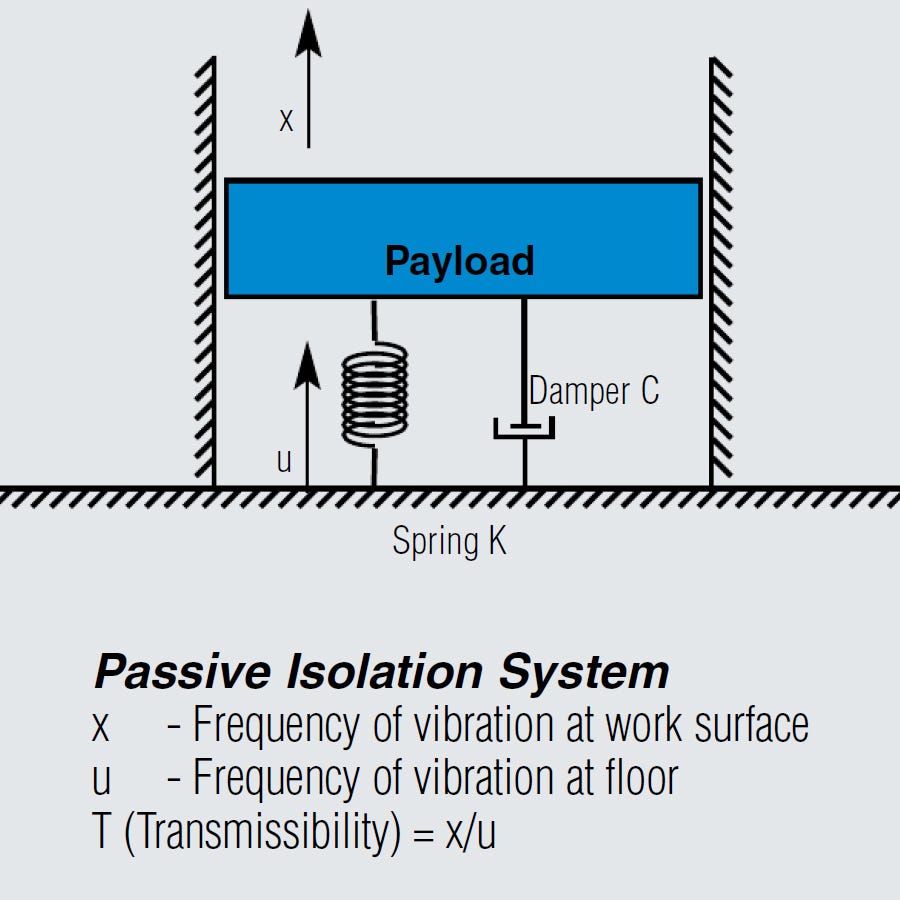

Passive Vibration Isolation

x Frequency of vibration at work surface u Frequency of vibration at floor T (Transmissibility) = x/u

The most common type of vibration isolator is the pneumatic isolator, which contains a sealed and pressurized air volume and movable piston. A rolling diaphragm membrane provides an airtight seal between the isolator and the piston. Compressed air pushes against the piston to support the system static load. Damping is provided by forcing air to move between chambers through one or more small orifices and/or a pendulum rod within a viscous damper.

Simply stated, the key to isolating vibration is to develop vibration isolators that attain the lowest possible natural frequency with the best isolation possible. The lower the natural frequency, the greater the ability of the isolation table to resist a disturbing frequency (resulting from loud noises, traffic, falling objects, etc.).

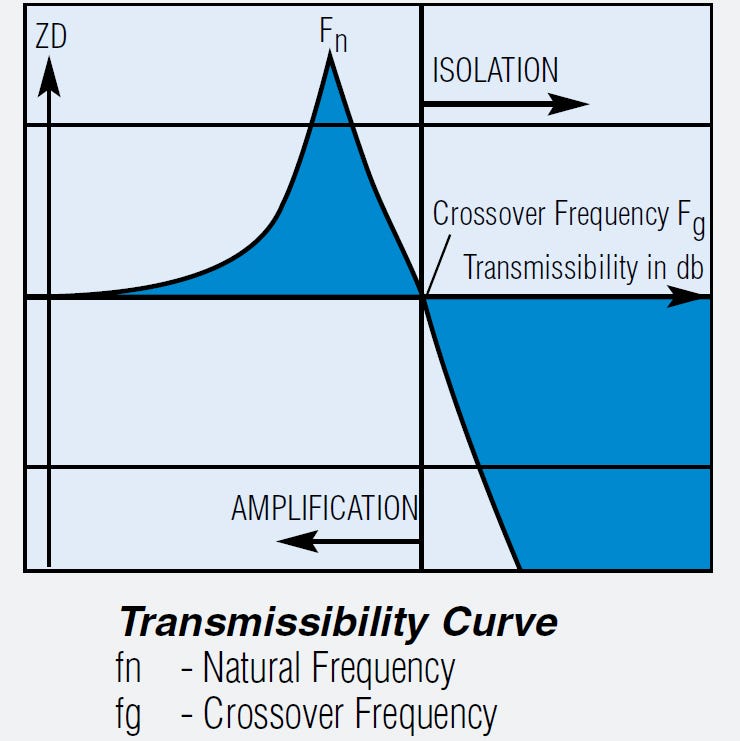

fn - Natural Frequency fg - Crossover Frequency

Natural frequency is the rate of movement (in cycles per second) at which a mass-spring system will vibrate if it is disturbed. The damping mechanism in the system will eventually damp out these oscillations.

As long as the disturbing frequency is higher than the natural frequency, the surface will isolate the vibration. When disturbing frequencies approach and then fall below the natural frequency, however, the isolators in the vibration table will amplify the disturbing frequency, increasing the vibration of the work surface.

Vibration isolation effectiveness is demonstrated graphically by a transmissibility curve which plots the ratio of system motions to ground motion as a function of frequency. In the transmissibility curve shown, the crossover frequency is the frequency at which the motion of the isolated system is the same as the floor motion (transmissibility = 1).

For optimal results, then, the desirable characteristics of a pneumatic isolator are a low natural frequency, a low amplification at resonance, and a fast roll-off of vibration transmission at higher frequencies. These are precisely the characteristics engineered into our line of passive vibration isolation tables and platforms.

Any disturbing force with a higher frequency will be isolated; the pneumatic isolator will transmit only a small fraction of the floor vibration to the isolated system. This isolation efficiency approaches 99.9%, depending on the load and the disturbing frequency.

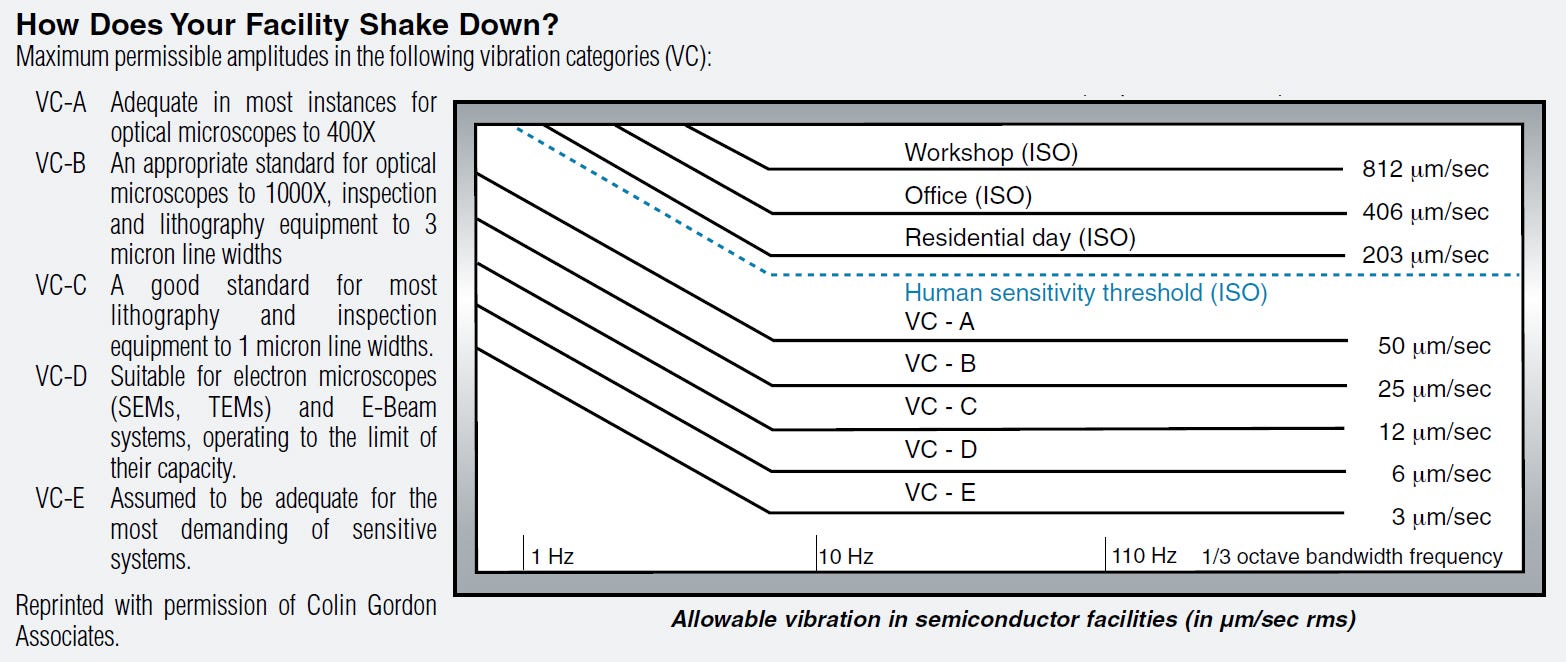

Allowable vibration in semiconductor facilities (in µm/sec rms)

- VC-A: Adequate in most instances for optical microscopes to 400X

- VC-B: An appropriate standard for optical microscopes to 1000X, inspection and lithography equipment to 3 micron line widths

- VC-C: A good standard for most lithography and inspection equipment to 1 micron line widths.

- VC-D: Suitable for electron microscopes (SEMs, TEMs) and E-Beam systems, operating to the limit of their capacity.

- VC-E: Assumed to be adequate for the most demanding of sensitive systems Reprinted with permission of Colin Gordon Associates.