Learn More: PlateCrane Applications

More Information

Designed for the scientist while maintaining the reliability and flexibility required by automation specialists, the PlateCrane integrates easily with automation-friendly incubators or random access stacks (plates are stacked in shelves for random selection) and Hudson’s LabLinx track-based system.

The PlateCrane EX is supplied with Hudson’s SoftLinx laboratory automation software that provides scheduling capability and an easy-to-use icon-based drag-and-drop Method Editor. SoftLinx users can access Hudson’s software interfaces for more than 150 microplate-based instruments, including liquid handlers, pipettes, washers, readers, incubators, sealers, bar code labelers, and more.

With the optional teach pendant, calibration is almost as easy as pressing a button. While servicing one instrument or an entire workcell, the PlateCrane Ex is the ideal solution for labs working with liquid handling instruments and microplates.

PlateCrane EX & EX360 Applications

Automated microplate robots such as the PlateCrane are used widely in the drug discovery industry to increase the efficiency of numerous high throughput screens involving complex methods (FLIPR, Reporter, ELISA, and FRET assays). The PlateCrane, designed with an efficient built-in plate gripper and on-board controller, pioneered the idea of a compact microplate robot handling and being compatible with multiple instruments from different manufacturers.

PlateCranes are also used to track microplates in their assays by automating the application of barcode labels to microplates and automatically delivering batches of up to 450 microplates to barcode print-and-apply devices, such as the Computype LAP-4100.

The PlateCrane is also used to move microplates and filter plates in high throughput, automated DNA Plasmid Prep systems. Unlike systems offered by some plasmid prep kit manufacturers, Hudson’s wide array of automated dispensers, shaker nests, and automated vacuum nests make PlateCrane-based plasmid prep systems truly walk-away with no need for human intervention from start to finish, with throughput as high as 6 quantity of 96-well plates (576 samples) per hour.

Additional applications:

- Moves plates with lids to-and-from stacks and can automatically remove the lid from the active plate

- Creates flexible, scalable, easy to operate, and affordable customized microplate handling solutions

- Flow cytometers—Automate and expand the process of moving plates to the Guava & Intellicyt instruments

- qPCR—Move plates into-and-out of Roche’s Lightcycler, BioRad’s CFX, or ABI’s 7900 instruments

- Liquid handlers—quickly and easily expand capabilities of existing liquid-handling systems with the PlateCrane

- Plate readers—Remove lids, set up time point assays and create multiple instrument workcells

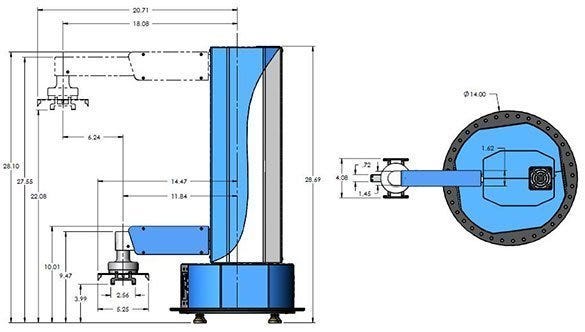

Diagram showing the movement and dimensions of the PlateCrane Ex cylindrical robot arm

| Plate Capacity: |

|

|---|---|

| Plate Format: | Portrait & Landscape (Rotary Gripper) |

| Plate Storage Device: | 2 removable stacks (expandable up to 15) |

| Housing Material: |

|

| Gripper Material: |

|

| Arm Mechanism: | ball bearing axis with high-speed screw rail; mechanical stops to prevent continuous rotation (345° maximum) |

| Arm Motion (Rotary Travel): | PlateCrane EX with 345° horizontal rotation PlateCrane 360 model with 360°+ (unlimited) rotation |

| Horizontal Reach: | 12"–18" radius from centerline |

| Vertical Reach: |

|

| Dimensions: | 27"H x 19"W x 27"D |

| Weight: | 45 lbs., without stacks |

| Operating Temperature: | 15° to 40°C (59° to 104°F) |

| Operating Humidity: | 0 to 85%, non-condensing |

| Computer Interface: | RS232 serial cable |

| Power Input: | 115/220V AC, 50/60Hz |