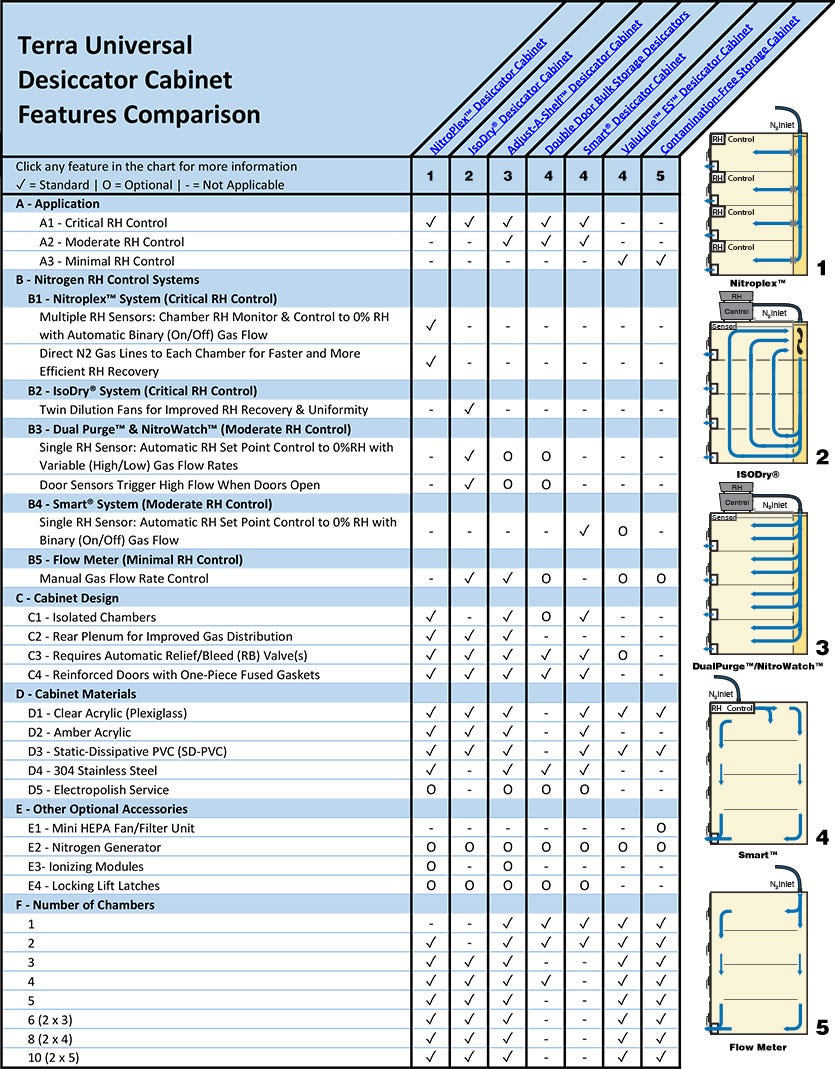

Desiccator Cabinet Features Comparison

A – Application: Which Desiccator is Best for My Application?

(back to chart)

Cost vs. Control: Terra Desiccators Simplify Your Choice

You need to protect sensitive samples, but you don’t want to overpay. Below is a list of application descriptions to help choose the best desiccator storage system for your application and budget.

A1 - Critical Control Demands:

For applications that require not only a low-RH set point, but a system that recovers it quickly when doors open/close, allows a different set point in each chamber, and/or protects against static and particulate contaminants.

Typical Applications

- Low exposure tolerance: Microelectronic or pharmaceutical samples that degrade very quickly when exposed to moisture.

- High access frequency: Doors open/close before system can recover target set point level.

- Exposure testing: Requires a separate %RH monitor/control in each desiccator chamber.

- ESD-sensitive parts: Minute static discharge results in severe degradation, cuts yields.

- Sterile and/or Particle Sensitivity: Critical contamination requirements won’t tolerate materials that shed particles or corrode.

A2 - Moderate Control Demands:

Sensitive samples may require automatic low humidity set point control, but low access frequency minimizes the need for faster RH recovery time. Protection against ESD and/or particulate contaminants may also be required.

Typical Applications

- Low-Moderate exposure tolerance: Low humidity and automatic monitoring is required. Microelectronic or pharmaceutical samples that degrade when exposed to moisture.

- Moderate-High Access Frequency: Parts are accessed on a daily basis and/or are sensitive to moisture exposure when doors are opened.

- ESD-sensitive parts: Minute static discharge results in severe degradation, cuts yields.

- Sterile and/or Particle Sensitivity: Critical contamination requirements won’t tolerate materials that shed particles or corrode.

A3 - Minimal Control Demands:

You need occasional nitrogen purging or desiccant to bring down the RH, or you may only need a dust-free enclosure without humidity control.

Typical Applications

- Moderate-High exposure tolerance: Low humidity and/or automatic monitoring is not required.

- Low Access Frequency/Extended Storage: If low humidity is required, fast recovery time is not, because doors are rarely opened: you stock the sample and come back for it days or weeks later.

- Moderate Static Protection: Availability of static-dissipative materials a plus, but ionization not required.

- Dust-Free Conditions: Samples require a clean environment, but chrome plating and adhesive seals are acceptable.

Additional Application Considerations:

For critical moisture control applications, relative humidity (RH) set-point recovery time is one of the most important considerations to achieving the required quality, safety, and shelf life of stored materials.

RH recovery is the time needed to reach an RH set point after a desiccator chamber or cabinet is accessed. A fast RH recovery time minimizes exposure of stored materials to harmful moisture levels. Thus, the ideal desiccator quickly and efficiently reaches and maintains the desired RH level.

Set-point recovery time depends on several variables listed below. Keep these factors in mind to choose the best desiccator storage system for your application and budget.

- Internal & External RH:

The desired internal RH set point depends on industry and application. Extremely low humidity requirements (under 10% RH) are more difficult to achieve and generally call for a Smart controller option to optimize recovery time and efficiency.

The greater the gap between required internal RH and ambient RH, the more time and inert gas will be needed to remove moisture from inside the desiccator. For example, a desiccator in a more humid ambient environment will have more moisture in the air to displace, and will therefore require more nitrogen gas or a more efficient humidity control system than one in a less humid environment.

- Access Frequency & Duration:

RH set-point recovery time is affected by the need to access parts inside the desiccator cabinet. Each time a door is opened, moisture-laden air, often bearing particles, enters the exposed chamber. The longer a door is left open, the more ambient air can flow inside. Once the door is closed, depending on the cabinet design, moisture can migrate from chamber to chamber, raising the internal RH throughout the cabinet.

During periods of frequent or prolonged access, a poorly configured desiccator may never attain the required RH set point, posing a serious threat to quality, safety, or shelf life of stored materials.

Choosing an appropriate automatic RH control system and cabinet design will help mitigate problems caused by frequent access.

- Desiccator Cabinet Size & Chamber Configuration:

The size or volume of your desiccator will determine how much ambient air needs to be displaced to reach your target RH set-point. Thus larger desiccators typically require more nitrogen or a more efficient RH control system, than smaller ones.

Furthermore, the chamber configuration can have a significant effect on time to reach set-point. Isolated chambers tend to be more efficient, as opening one chamber will not expose other chambers in the cabinet to ambient air. Non-isolated chambers that share the same air space will generally take longer to recover after one door is opened, as ambient air can more easily circulate through the entire cabinet.

- Nitrogen Gas Expense:

Users seek to achieve a low RH set-point as efficiently as possible to reduce wasteful gas consumption. Unfortunately, unassisted RH control systems require significantly higher consumption of nitrogen gas to reach the desired relative humidity set-point. This problem compounds with high access frequency.

High nitrogen gas consumption drives up overhead cost and can lead to other operational problems. For instance, those who rely on gas canisters will need to plan for more frequent replacements and will be suseptible to dealing with supply shortages.

A smart control system automates the process to conserve nitrogen and reduces costs by up to 78%. A nitrogen generator can also eliminate the supply shortage issues from dependence on pre-filled gas canisters.

- Cabinet Material Type:

Material type can also affect relative humidity inside a desiccator cabinet. The more porous or hygroscopic a material, the easier it is for gases and moisture to transfer through. Many plastics such as acrylic may appear impermeable to the naked eye, however are porous enough at a molecular level to absorb moisture that can then permeate into the chamber. The diffusion or passage of moisture through acrylic can occur in a few ways listed below. The higher the difference between moisture levels, and the greater the exposed surface area, the higher the rate at which moisture will enter the chamber.

- Walls inside the cabinet can absorb moisture from ambient air already inside the cabinet, and then release the moisture after the cabinet is purged with a dry inert gas.

- Moisture can permeate through the walls from the outside (higher moisture) to inside (lower moisture).

- Walls can absorb moisture from direct contact with water (either inside or outside the cabinet).

Critical moisture control applications concerned with moisture vapor transmission rate (MVTR) should consider a vapor impermeable cabinet material such as stainless steel to achieve the required quality, safety, and shelf life.

B – Nitrogen RH Control Systems:

(back to chart)

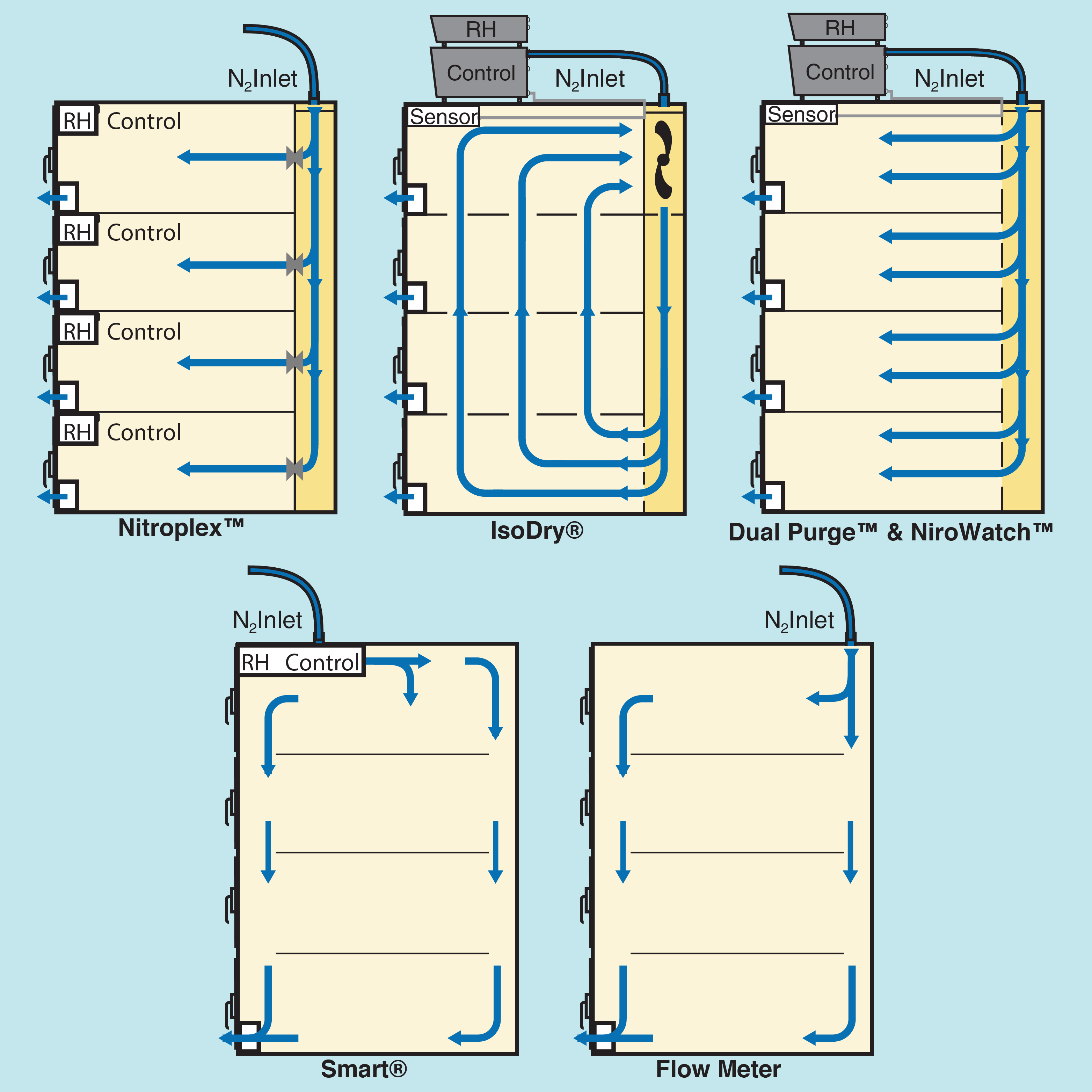

B1 – Nitroplex™ System

NitroPlex™, Terra’s most efficient humidity control solution, is designed for the most demanding critical moisture control applications. The system features multiple RH sensors modules to allow RH monitor & control to 0% RH in each isolated chamber. The modules use automatic binary (on/off) valves to quickly and efficiently direct N2 gas where and when it’s needed. The ability to establish separate humidity set points in each storage chamber allows for storage of parts with differing moisture sensitivities and conservation of N2 gas in chambers that are not in use.

B2 – IsoDry® System

IsoDry® upgrades the Dual Purge™ & NitroWatch™ system by adding twin dilution fans for drastically improved RH recovery & uniformity. The fans rapidly mix and circulate incoming nitrogen gas to accelerate moisture removal and achieve uniform RH throughout the entire cabinet. The door sensors de-activate the dilution fans when a door is open to minimize the spread of incoming moisture and contaminants throughout the cabinet.

B3 – Dual Purge™ & NitroWatch™

This system is designed for larger cabinets. Like the Smart® system, it features a single RH sensor for automatic RH set point control to 0%RH. The Dual Purge™ has two gas flow settings (high/low) to rapidly reach and then maintain the user-specified set-point. Door sensors trigger high gas flow when doors open to help protect against the entry of contaminants, and expedite set-point recovery. Because this system includes only 1 RH sensor, the displayed RH reading may not accurately reflect the RH in other chambers of the cabinet.

B4 – Smart® System

Terra’s Smart® desiccator system features a built-in RH Sensor to provide automatic RH set point control to 0% RH with binary (on/off) gas flow. The automatic RH set point control minimizes necessary supervision and increases efficiency of N2 gas consumption. The system is recommended for smaller cabinets with 1-2 chambers. This single gas inlet system can encounter inefficiencies with gas distribution and RH uniformity in larger cabinet systems.

B5 – Flow Meter

A manually controlled flow meter offers the lowest up-front cost for RH control. It is most suitable for smaller desiccators that do not require much nitrogen gas or those that require minimal supervision. Manual control means humidity control is more prone to human error and not as efficient with the consumption of inert gas, which can lead to damaged products and high operating costs.

C – Cabinet Design

(back to chart)

C1 – Isolated Chambers

One way to improve moisture control and recovery is to compartmentalize a cabinet into isolated chambers. The multiple air spaces are thus independent and RH in one chamber is unaffected by access to adjacent chambers.

C2 – Rear Plenum for Improved Gas Distribution

Larger desiccator cabinets with single gas inlets are more susceptible to RH control problems caused by uneven gas distribution. A rear distribution plenum helps alleviate these problems. Instead of feeding a gas line directly into 1 chamber, the gas inlet feeds into a narrow wall plenum adjacent to all chambers. The plenum pressurizes and simultaneously distributes gas through small perforations in the wall to every chamber in the cabinet. Distribution plenums also allow for isolated chambers (mentioned above).

C3 – Requires Automatic Relief/Bleed (RB) Valve(s)

RB valves provide continuous pressure relief while also functioning as a one-way check valve. Installing one on each chamber improves moisture and contamination control. Any contaminants that enter through an open door can exit out the same chamber without migrating to other areas. Desiccator cabinets with isolated chambers require one RB valve per chamber to safely de-pressurize and ensure rapid RH recovery.

C4 – Reinforced Doors with One-Piece Fused Gaskets

This seemingly small detail makes a big difference, as it is one of the most common features likely to break or malfunction on a desiccator cabinet. An unidentified leak or non-functioning “out of service” desiccator cabinet in a worst case scenario can lead to an extremely costly loss of materials. Through 40 years of refinement and attention to detail, Terra’s desiccator cabinets have been designed and tested to perfect this important feature for guaranteed long-lasting, easy to maintain, and reliable operation.

Desiccator cabinets reinforced with stainless steel frames lend rigidity for an improved seal, and extend the service life of the entire cabinet. Heavy-duty lift latches easily close to produce a strong seal and prevent metal-on-metal scraping common with rotary latches. The ergonomic design also minimizes stress on your wrists and pinching of fingers. Optional locking lift latches are also available (specify one per chamber). The door frame is lined with a one-piece durable, resilient, and chemical resistant “e” shaped rubber gasket. This flexible gasket compresses to provide a tight seal and is mechanically attached to the door so it won’t slip, peel, or deform over time. The doors are also completely removable for further cleaning, maintenance or repair.

D – Cabinet Materials

(back to chart)

D1 – Clear Acrylic (Plexiglass)

Low cost and lightweight acrylic offers durability (17x impact resistance of glass) and superior clarity. The transparent walls help quickly find items anywhere inside, even those hiding in the back or bottom of the cabinet. Acrylic’s two main drawbacks (hidden costs) are low chemical resistance (acrylic is damaged by alcohol and many other cleaning agents), and poor protection from electro-static discharge (ESD).

D2 – Amber Acrylic

Amber acrylic adds to the benefits of clear acrylic by filtering out UV and blue light to protect light sensitive materials from degrading, or changing composition. Similar to clear acrylic, it shares the same two drawbacks: low chemical resistance and poor protection from ESD.

D3 – Static-Dissipative PVC (SD-PVC:

SD-PVC not only dissipates static charges safely but also eliminates the particle attraction that static charges create. Surfaces stay clean, inside and out, making this material perfect for use in cleanrooms. SD-PVC is transparent and highly durable, it can be used in place of acrylic in nearly any application. It features a surface resistivity of approximately 10^7 ohms per square and is completely non-contaminating—with no measurable outgassing—and it resists a wide range of chemicals such as alcohol and other common cleaning agents.

D4 – Stainless Steel

Stainless steel desiccator cabinets have many benefits. They are ideal for heavy duty storage applications of large, bulky materials. Stainless steel is also suitable for sterile applications. It resists most harsh chemicals and alcohol-based cleaning agents, and won’t produce contaminants during sterilization. Lastly, unlike plastics, stainless steel is impermeable to moisture and therefore suitable for the most critical low humidity storage applications.

Terra offers 304 and 316L stainless steel. 316L-grade contains more nickel and molybdenum than 304-grade, enhancing its resistance to corrosion in wet environments, degradation from bleach-based disinfectants, and high-temperature sanitation, like autoclaving.

D5 – Electropolish Service

Electrochemical polishing improves the surface finish of stainless steel for increased chemical resistance, to support easy sterilization and reduce micro-cavities where microbes can colonize.

E – Other optional Accessories

(back to chart)

E1 – Mini HEPA Fan/Filter Unit

High Efficiency Particulate Air (HEPA) Filter: 99.99% efficient at 0.3µm particle diameter

E2 – Nitrogen Generator

Compact and portable nitrogen generators eliminate the need for costly nitrogen gas cylinders and minimizes the risk of unplanned supply shortages. They provide complete control over rate and purity of nitrogen gas from 95% to 99% purity.

E3 – Ionizing Modules

Ionizers can be installed into the rear gas distribution plenum of a desiccator cabinet to help neutralize electro-static surface charges throughout a desiccator cabinet.

E4 – Locking Lift Latches

Locking Lift Latches help prevent unauthorized access to sensitive or valuable materials. Different keys can be assigned to each chamber for added security. Chambers can be further reinforced with locking brackets (for padlocks) and tamper-proof hinges.

F – Number of Chambers

(back to chart)

Terra stocks standard chamber configurations for each line of desiccators. In general, larger desiccators typically require more nitrogen or a more efficient RH control system, than smaller ones.

Terra Universal is the leading expert in the design and fabrication of ISO rated cleanrooms, furnishing and supplies.

Get a free consultation from one of our cleanroom specialists:

Call (714) 459-0731